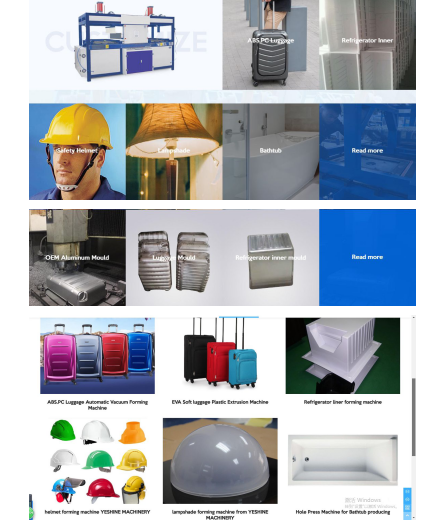

Yeshine Luggage Forming machine is a common mechanical equipment in the luggage bag production line. Grasp the operation points of the forming machine and use the forming machine correctly and reasonably.

The operation of luggage forming machine includes a series of links such as machine installation, adjustment, test run, operation, maintenance and repair, and special attention should be paid to its characteristics when using the forming machine.

Preparatory work for the operation of the forming machine

(1) luggage bag for extrusion molding.

The original fastener should meet the required drying requirements, and further drying is required if necessary.

The raw materials are sieved to remove agglomerates and mechanical impurities.

(2) When operating the machine, check whether the water, electricity, and gas systems in the equipment are normal to ensure that the water and gas paths are unblocked and leak-free, whether the electrical system is normal, whether the heating system, temperature control, and various instruments work reliably;

Auxiliary engine runs at low speed with empty car to observe whether the equipment is operating normally; start the vacuum pump of the setting table to observe whether it works normally; add oil to lubricate the smooth parts of various equipment. If a fault is found, remove it in time.

(3) Install the head and sizing sleeve.

According to the variety and size of the product, select the specifications of the machine head.

Install the machine head in the following order.

The operation of the blister machine can be started after the constant temperature. The machine head and the flange bolts of the blister machine should be tightened again before starting to eliminate the difference in thermal expansion between the bolt and the machine head. The order of tightening the head bolts is diagonally. The force should be even. When tightening the flange nuts of the machine head, the tightness of all sides must be consistent, otherwise the material will run out.

(4) When the forming machine is in operation, press the "Ready to Drive" button, then connect the "Start" button, and then slowly rotate the screw speed adjustment knob, the screw speed starts slowly. Then gradually speed up, while adding small amounts. Pay close attention to the indication changes of the host ammeter and various indicator heads when feeding. The screw torque cannot exceed the red mark. During the operation of the blister machine, no one is allowed to stand directly in front of the die before the bag profile is extruded, so as to prevent injury accidents caused by broken bolts or wet raw materials. After the luggage is formed from the mould of the machine head, the extrudate needs to be slowly cooled and led to the traction device and the shaping die, and these devices are activated. Then according to the indicated value of the control instrument and the requirements for extruded products. Adjust each part accordingly to make the entire extrusion operation reach a normal state. And add enough material according to needs, the operation of the twin-screw blister machine adopts a metering feeder to feed evenly and at a constant speed.

More info about luggage making machine, welcome to contact Yeshine, top luggage machine manufacturer in China:

WhatsApp:+8613989711960/18867757225

Email add: Crystal@wzyeshine.com; machine@wzyeshine.com

Qianbu Village, Xincheng Street, Ruian, Wenzhou City, Zhejiang, China

Copyright © 2019 WENZHOU YESHINE MACHINERY CO.,LTD | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.