Travel luggage production process

1. Box cover fee

Materials, equipment: ABS + PC sheet extruder machine, vacuum forming machine, cutting machine

Forming process: plywood, board cutting, molding, cutting and processing

2. Iron frame

Materials, equipment: iron alloy mold material, box-wrapped iron frame

Molding process: mold material bending frame, cutting edge, joining frame, drilling hole, slinging, anzou area

3. Assembled box

Manual assembly box, Japanese iron frame, equipment “booking machine” type connection

4. Anchor stand foot,wheel,trolley

Equipment striking iron, hand-held point movement screw

5. Invoice

Filling inside the cut, water inside the box, inside the hand glue, near the inside of the welded part

6. Viscous frame protection

Selection option, price tag ,scissors

7. Affordable lock, handle, bolt

Hand-held electric drive screw, box lock, grip, grip back reinforcement

8. Travel box demand communication 8 types test

Test the demand for the box package.

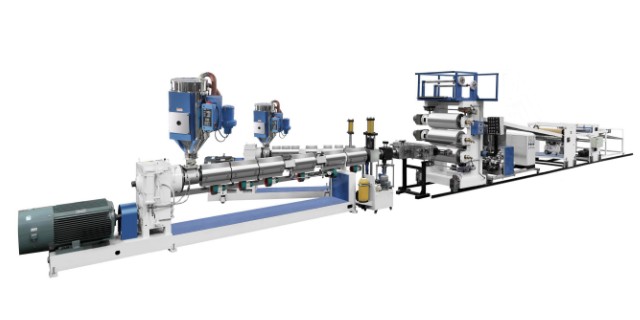

Yeshine New Style Luggage Plastic Sheet Extruder Machinery For Luggage Making Production Line

Process: Raw Material - Heating&drying - Co-extruder&shape - cooling&hauling -cutting-finished sheet

Machine feature:

ABS one line sheet extruder machine is capable of producing ABS new or recycled material in single layer sheet. It is widely used in Luggage , Suitcase, Trolley bag ,Refrigerator, Air condition,bathroom production.

Copyright © 2019 WENZHOU YESHINE MACHINERY CO.,LTD | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly,our online wechat or WhatsApp:8613989711960.