YESHINE 8-head Punching Machine Commissioning and Detection Shipped to Indian customerYESHINE The latest customized 8-head punching machine is being Final testing in progress and inspected and . It can punch and punch trolley,wheels,handle,logo and all luggage accessories!Official Website:

www.yeshinegroup.com

www.yeshineparts.com

Wenzhou Yeshine Machinery Co.,ltd

Founded in 1989year.

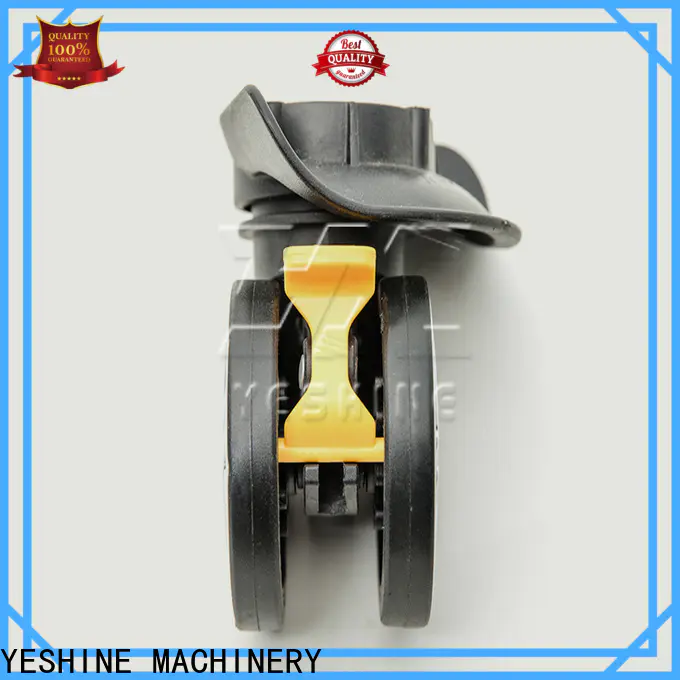

Specialized in manufacturing Whole Line Luggage Making Machine: PC/ABS Plastic Sheet Extruder Machine, Vacuum forming machine, Cut and Hole Punch Machine, CNC robot machine and Supply all Luggage Accessories(Injection Mould, Trolley, Wheel, Handle, Lock etc)

We are the leader and first one export to Overseas!

Welcome for contacting us:

Crystal Cai

Mob./Wechat/Whatsapp:

+8613989711960

Email: crystal@wzyeshine.com;crystal.xxmachine@hotmail.com

Skype: cai.menglu1/ flyingruan1

Connect With Me On Social Media:

https://m.facebook.com/?_rdr#!/crystal.cai89

https://www.instagram.com/ccrystal_luggage_machinery/

https://www.linkedin.com/in/crystal-cai-luggage-machine-4ab554126/

Read More>>

All Products

- Best PRODUCTS

-

Quality PRODUCTS

-

Certificated Luggage Wrapping Machine

-

Certificated ABS Luggage Bag

-

Hot Luggage Accessories Wholesale

-

Luggage Parts Exporter

-

Top Luggage Making Machine Manufacturer

-

Auxiliary Machine For sell

-

CNC Router Machine Company

-

Hot Hole Punch Machine

-

Luggage Cutting Machine Factory

-

Quality Plastic Sheet Extruder Machine

-

Customized Vacuum Forming Machine For sell

-

Certificated Luggage Wrapping Machine