ABOUT US

Quality, service and reputation are the basis and guarantee for us to win the market and customers.

WENZHOU YESHINE MACHINERY CO.,LTD

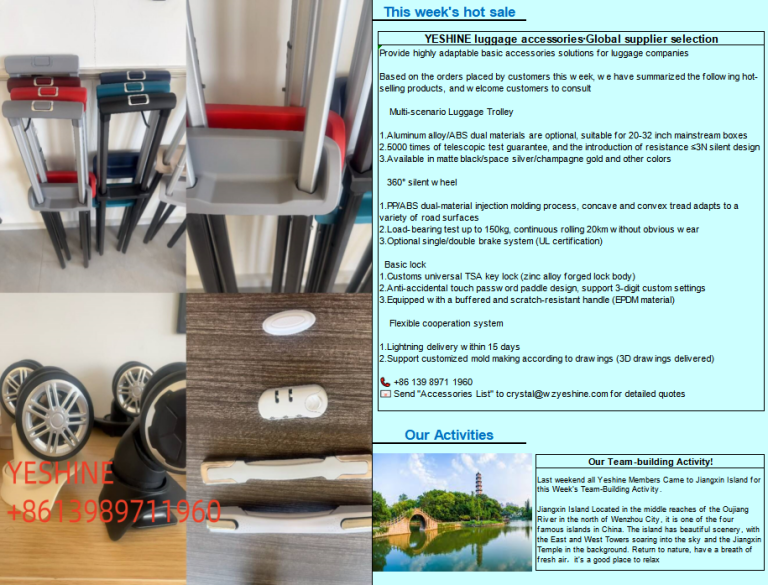

WENZHOU YESHINE MACHINERY CO.,LTD is located in Ruian City, Zhejiang Province, which is specialized in manufacturing Whole Line ABS.PC trolley Case/Suitcase/Luggage Making Machine in production. It has included Plastic Sheet Extruder Machine, Vacuum Forming Machine, Cutting and Hole Puncher Machine, fabrication machine,luggage Trolley,Wheel,Handle,Lock,ect

We trust that we are the Leader who is majored in supply whole line details in luggage industry in china.

According to market need, we develop our Suitcase Making Machine and other products all the time and support customized design.

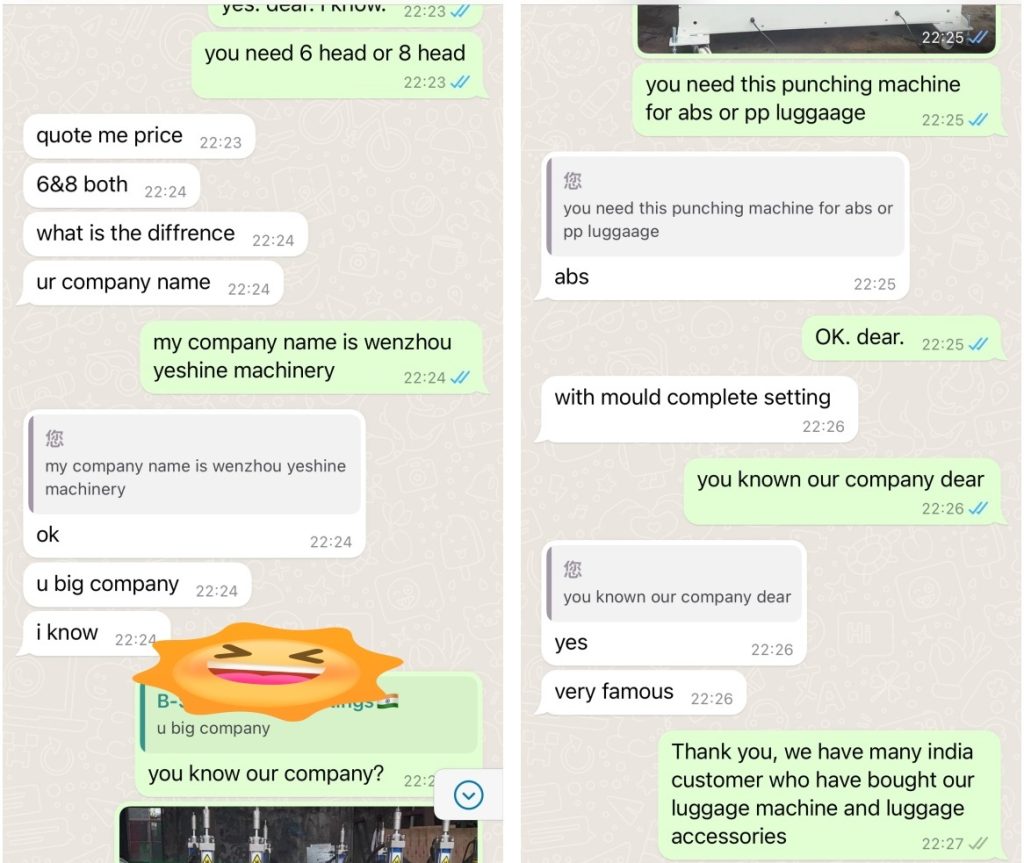

Our whole line machine has been widely exported to Turkey, Algeria,Morocco,Thailand,India etc.

With high approval get from our customers,we are growing more and more powerful, has passed CE,ISO9001:2008.

We are always struggling the first leader supplier of Whole Line Luggage making Machine in china. We manufacture the machinery of our customer with Quality Assurance, Delivery Accuracy & Cost Effectiveness&fast after-sale service

WELL-EXPERIENCED

Established in 2005.Focus on Luggage Industry for more than 18 years.

CERTIFICATES

ISO Certificate SGS Certificate CE Certificate etc.

OUR SERVICES

Efficient and professional sales team, Offer after-sale service.

NEWS

We are honored to Set up your luggage Production to add value to your business.

Dragon Boat Festival: A Vibrant Celebration of China's Millennium Tradition

Ingenuity Builds Dreams and Intelligently Creates the Future - WenZhou Yeshine Machinery Co., Ltd.

Request A Quote

CONTACT US

- +86-577-65526292

- +8613989711960/18867725393(Whatsapp/Wechat)

- Crystal@wzyeshine.com; parts88@wzyeshine.com; yesluggage@wzyeshine.com

- Qianbu Industrial Zone , Xincheng Street, Ruian,Wenzhou City, Zhejiang,China