company capabilities (dunn industries inc.-hi-tech group).

by:YESHINE

2020-06-09

Dunn Industrial

123 Abby Road, Manchester, NH 03103 Tel :(603)666-4800 Fax: (603)666-4884 E-

Mail: Message @ dunnindustries. com Web: www. dunnindustries.

Com life statistics year of establishment: 1987 employees: 15 facilities number: 1 who are we [

Slightly] Illustrations

Dunn Industrial

Thermoplastic pipe manufacturers in the medical device industry provide prototypes through production services.

The company produces single-lumen or multi-lumen tubes up to 0. 400 in.

OD meets customer specifications accurately and consistently.

Dunne industries also offers raised tubes, stripes, co-extrusion and surplusextrusion.

ISO 9001: 2000 certification.

The main markets of medical, pharmaceutical, aerospace, marine, telecom, industrial services provide medical grade pipes produced by a variety of engineering plastics, including: Ethal, Tecoflex [R]

Polyester Fiber, polyester fiber [R], Lexan[R], Plexiglas[R], C-Flex[R], Texin[R]

, Polypropylene, Rilsan [R]

, EVA, high density polyethylene, low density polyethylene, llannan, PETG, peguan3 [R]. ,Isoplast[R],, Hytrel[R]

, Or your custom compound. [

Slightly] Illustrations

Dunn Industries is your custom extrusion specialist, able to offer a wide range of applications in pipe sizes as small as odds0. 010\" x ID\'s 0.

005 \"is as big as 0. 250\".

When scale is critical, we have expertise and are backed by our solid reputation to get the job done on time and within budget.

Your guarantee is the quality policy of Dunn industry, which will exceed the unparalleled quality requirements and expectations of our customers in our products, services and relationships.

Just minutes from Manchester, NH Airport, Dunn industries\'s state-

Arts extrusion facilities enable us to better serve our customers across the United StatesS.

All over the world.

Our continuous flexibility and reliability to meet the needs of the rapidly changing medical field, coupled with our experienced staff and superior equipment, gives Dunn industries the ability to meet your needs

For more information, please provide price quotes and samples immediately. www. dunnindustries. com [

Slightly] Illustrations

Eagle brand stainless steel pipe Manufacturing Co. , Ltd.

Tel: No. 10 Franklin exploration Road, 02038 (800)528-8650 Fax: (508)520-1954 E-

Postage: generalsales @ eagletube. com Web: www. eagletube.

Com life statistics year of establishment: 1982 employees: 70 facilities: 1 who are we [

Slightly] Illustrations

Eagle stainless steel pipe Manufacturing Co. , Ltd. based in Franklin, Massachusetts

26 years of service to healthcare, aviation and high-tech manufacturing customers are being celebrated.

On the record.

On-time delivery, fair pricing, product quality and highly skilled staff committed to continuous improvement and training, Eagle has earned a reputation as a preferred supplierthe-

Stainless steel products and manufacturing stainless steel components.

As ISO 9001: 2000, as 9100: 2000 certified and six iconic drive manufacturing plants, you can rest assured that at every step of our factory, every employee of ours cares about the quality of every product.

Main market * Medical * high-tech manufacturing services provided by aerospace * stainless steel pipes shipped from a large inventory (

Pipe, Bar material, hollow rod, pipe, flange, fittings, custom size and shape)

* Precision cutting-to-

Length pipes * custom made stainless steel parts * pipes of custom shape and size * stainless steel rice pipes * square and rectangular pipes * bending, cutting, CNC machining, laser welding and cutting, grinding assembly and more.

Eagle specializes in the production of stainless steel, high nickel alloy and titanium components.

No voicemail!

When you call Eagle, hope to talk to a friendly professional who speaks your language and is ready to respond to your needs.

Whether you need the details of our capabilities or inventory details, you will get the answer immediately! www. eagletube. com [

Slightly] Illustrations

1071 Newtown, edge medicine center, 1376 Lindenhurst Road, postal box, PA 18940 Tel :(215)579-5700 Fax: (215)579-7350 E-Mail: info @ edge-pdc. com Web: www. edgemedica.

Com life statistics year of establishment: 1985 employees: 30 facilities quantity: 2 years sales: $4 million who are we [

Slightly] Illustrations

EDGE Medica is ISO 9001-

2000 certified design and engineering companies that comply with fda cfr Title 21, part 820 design control and quality system regulations.

EDGE Medica provides venture capital for early development of mechanical and electrical and disposable medical equipment for companies and industry leaders.

EDGE Medica offers an experienced team of professionals to help you bring your medical products to market-fast.

Our innovative approach is to work with strategic partners at an early stage and take advantage of more experienced

From the initial concept to production, the discipline team to the development project.

Main market * Biotechnology/laboratory equipment: Anthrax detector, cell culture system * Interventional Cardiology: Stent importer, arterial closure, endoscopic vascular collection * Oncology: biopsy device, thermal ablation catheter, cranial magnetic stimulation * Orthopedics: orthopaedic implant guide, spinal disc fixation system * ophthalmology: Ophthalmology laser system * drug delivery: * digital ultrasound system provided, neonatal care equipment, blood analyzer services * Patient Monitoring and Diagnostic Equipment

Slightly] Illustrations

Engineering * technical assessment/assessment and advice--

* T Wireless Technology * Mechanical Engineering-Software development and system integration-Mechanisms--

Mechanical and electrical motion Research * electrical engineering--

Embedded Controller-

Analog, digital and photoelectricelectronics--

Signal acquisition and processing * CAD modeling and finite element analysis * fluid and Optical Design * PCB design and layout * bio

Chemical sensor design and biological compatibility * high performance materials/composites * enhanced device performance * DFM/DFX design * Market and user research * product ergonomics research discovered through task analysis and product use scenarios * concept Makes * attractive, sales Drive product aesthetics * develop consistent home appearance for the entire product line * complex geometry CAD surface treatment * graphical UI design model and prototype * quick bread plate prototype for \"principle product\" demo * to customer appearance Model of equipment technology sold by investors * engineering prototype used for testing * Pre-

Production prototype for site evaluationedgemedica. com EFD, Inc.

Tel: (RI 977, 02914 Providence, East Waterman Avenue)800)556-3484; (401)434-1680 Fax: (401)431-0237 E-mail: info@efd-inc. com Web: www. efd-inc. com/pr/mddi-1207.

Established html life statistics year: 1963 employees: 280 facilities: Who are we in the world [

Slightly] Illustrations

For more than 40 years, EFD has been the world\'s leading manufacturer of precision dispensing systems for the control of adhesives, seals, lubricants and other assembly fluids.

By providing a reliable, cost-

The effective way is to apply the same number of assembly fluids on each part, each time, we help thousands of companies in hundreds of industries to increase production and process control, reduce rework and rejection

Medical device manufacturers in major markets around the world rely on efd\'s precision distribution system to apply assembly fluids in controlled, repeatable quantities.

Our customers found that, continuous application of propylene salts, adhesives, epoxy, silicone, coatings and other liquids helps to build tubes, sleeves, brackets, test strips, pacemakers with greater process control and less fatigue of workers.

Provide innovative products, excellent quality, experienced technical support and online services

Delivery time makes EFD a recognized leader in precision fluid distribution technology.

Products include: * Air-

Electric and positive displacement dispensers for making the bench assembly process more consistent.

* Reliable, low

The maintenance distribution valve that increases the output reduces the downtime of the automated production line.

* XYZ distribution system for automating desktop processes.

* One-time components (

Syringe barrel, piston and needle)

This brings superior quality and consistency to the process from product assembly to Saline Flushing catheter, resulting in the distribution of sticky material and monomer in eye applications. * High-

First improved quality solder paste

The electronic assembly process is generated through. [

Slightly] Illustrations

All components are precision formed with EFD\'s own silicone-free, latex-

Free American facilities.

In order to prevent residual pollution, no mold release agent is used during the manufacturing process. www. efd-inc. com/pr/mddi-1207. html [

Slightly] Illustrations

Elkan Medical

2 University Square, Suite 620 Hackensack, NJ 07601 Tel :(201)457-1120 Fax: (201)457-1125 E-

Mail: Message @ elcam-medical. com Web: www. elcam-medical.

Com life statistics year of establishment: 1970 employees: 200 people, with more than 20 engineers

Slightly] Illustrations

Elcam Medical is the world\'s leading OEM supplier of fluid management, drug delivery and vital signs monitoring systems and equipment.

Elcam is an innovative customer offering \"ideas for solutions\"centric, full-

Service partners with capabilities from design to manufacturing with special expertise in high volume precision molding, high speed assembly and laser applications.

In addition to our core products and capabilities, Elcam now offers custom design and sub-component services.

Our customers include the world\'s largest medical devices and pharmaceutical companies.

For more than 30 years, elcamsistently has been offering high quality products at competitive prices and all products are delivered on time.

Elcam serves intensive care, anesthesia, intravenous injection in major markets-

Market for interventional therapy, Interventional Cardiology, interventional radiology and medicine.

Services provided [

Slightly] Illustrations

Our product: * cock--

Standards 1, 2, 3 and 4-

Mode, washable, large bore, high pressure,-

Microorganisms and many custom options.

* Manifold * needle free--

* Angiography and PTCA valve unit * disposable pressure sensor and flushing unit * Automatic

Drug syringe * bottle cap--

Our ability: * high-

* High volume precision injection molding

Speed automatic assembly * laser drilling * LIM forming * welding * packaging * manual assembly * Design and Development * ultrasonic welding [

Slightly] Illustrations

Our commitment: * Custom Design * component services: * consistent quality over 30 years * customer satisfaction with excellent service and excellent communication * strong engineering support * on-time delivery * safe stock plan/consignment * In-

Please visit our website (www. elcam-medical. com)

For more information about our components, see

Components and complete revolving door solutions. www. elcam-medical.

Internet Technology Co. , Ltd.

New York Endicott Clark Street 1093, 13760 Phone :(866)820-4820 Fax: (607)755-7000 E-

Mail: ttaro @ eitnycom Web: www.

Interconnect.

Com life statistics year of establishment: 2002 employees: 2,1 O0 facilities quantity: 2 years sales: $0. 363 billion who are we [

Slightly] Illustrations

Effective vertical integration makes Endicott interconnect different from any supplier in the electronics packaging industry.

We are an expert in manufacturing and assembling complex printed circuit boards, advanced flip chip and lead key semiconductor packages, and manufacturing and integration of precision equipment.

We also provide unified services to supplement these products;

Design and layout, thermal, electrical and mechanical modeling, reliability and environmental testing, and physical analysis.

These products and services are available at any stage of the product\'s life cycle, from concept to endof-

Life, quick turn, and prototype functions are embedded in the core manufacturing operation.

This provides our customers with perfect and seamless scalability from the prototype, pre-production, and production stages without worrying about transfer facilities, processes, and support staff.

Major markets military/defense, aerospace, medical, IT and servers, semiconductor, advanced testing equipment.

Our solutions offer leading technology and the best servicein-

Quality, performance and reliability.

Products include printed circuit board manufacturing, electronic manufacturing assembly services, semiconductor packaging substrate manufacturing, and integrated circuit assembly services. [

Slightly] Illustrations

Although Endicott Interconnect is not common today, it is committed to developing new processes, technologies and technologies that drive progress in the electronics industry.

Our continued investment in inR & D helps to advance our technology leadership and deliver results in a truly visionary roadmap.

Since the establishment of November 2002, we have applied for more than 76 US patents and have so far obtained more than 36 patents.

Our advanced technology roadmap brings us to 2020 and we will continue to develop and nurture our alliance relationship with academia to support our remote technology efforts.

El\'s advanced laboratory service is a powerful combination of people, equipment and expertise with the mission of adding insight and value to product life design, qualification and life extension.

We provide comprehensive support services including mechanical and physical design and application engineering, advanced Laboratory Services, Worldwide

First-class turnkey manufacturing and R & D.

We are committed to providing support to our customers to complement our products and services. www.

Interconnect. com [

Slightly] Illustrations

EPIC Technologies 200 Norwalk OH 44857 East bluegrass Avenue Tel :(810)695-1521 Fax: (419)668-2891 E-mail: todd.

Bagut @ epictech. com Web: www. epictech.

Com life statistics year of establishment: 1988 employees: 2350 facilities quantity: 6 years sales: $0. 281 billion who are we [

Slightly] Illustrations

Over the past 20 years, EPIC Technologies has built a reputation for delivering world-class, high-quality electronics manufacturing services (EMS)

To the original equipment manufacturer (OEMs)

In the medical, industrial control, automotive, computer and telecom industries.

Over the past five years, we have tailored our streamlined business to the medium size and higher mixed segments of the target market.

Through successful implementation and continuous improvement of this synchronous stream manufacturing (SFM)

In the process, we provide customers with high quality products, when they want, where they want.

EPIC is the world\'s top ten suppliers of medical electronic devices, and we understand the needs of a diverse healthcare customer base.

The EPIC facility has been certified by ISO 13485 and registered by the FDA.

We are not

Manufacturers of medical instruments, automotive, industrial controls and telecom OEMs.

The services offered by EPIC are dedicated to providing our customers with comprehensive EMS solutions from design to manufacturing to direct fulfillment.

From the early days of the OEM product design cycle, we became an extension of the customer team.

EPIC assists engineering processes in circuit development, component selection, packaging, validation, and product testing to maximize functionality, reliability, and cost effectiveness.

These capabilities enable us to support our customer plans from concept to entire production cycle while providing critical mass to economies of scale by leveraging our purchasing power and shared resources. [

Slightly] Illustrations

The key advantage of EPIC is that we focus on lean production to achieve high throughput speed.

The basic premise is that the material that is actively converted into finished products is cost-effective, and the \"waiting state\" material inventory of the conversion is not high.

Therefore, our SFM process focuses on: * minimizing inventory of raw materials and finished products * optimizing the movement speed of production in the factory * promoting the ability to make immediate changes to products, minimize past and expensive rework.

EPIC\'s full range of services include: * product design support * New Product Introduction * PCB assembly * fault analysis * direct fulfillment/logistics * terminal-of-

Life support * Component Engineering * prototype component * test development * System Integration/box build * warrantyepictech. com [

Slightly] IllustrationsEtQ, Inc.

399 Conklin Street, Suite 208 Farmingdale, NY 11735 Tel :(516)293-0949; Toll Free: (800)354-4476 Fax: (516)293-0784 E-mail: info@etq. com Web: www. etq.

Who are we [

Slightly] Illustrations

EtQ is the leading enterprise quality and compliance management software for identifying, mitigating and preventing high

Respond to risks through integration, automation, and collaboration.

EtQ uses first-class products

Integration module and enterprise application integration for managing and measuring quality and compliance processes and performing organizational changes.

EtQ\'s mission is to make compliance management and business communication simple and efficient.

Founded in 1992, EtQ has a unique understanding of the quality and compliance process and has been working to make the overall quality operations and quality system better serve the business.

EtQ medical devices are an integrated quality and FDA compliance management system for major markets

Configured to specifically meet the needs of the medical device industry and exceed 21 CFR Part 11 and gmp requirements.

EtQ\'s unique modular approach offers unparalleled flexibility and automation.

Using the services provided by the unique FDA compliance software system for risk assessment EtQ simplifies the compliance process, aiming to minimize the number of CAPAs using advanced filtering models;

Features: * Automatic separation and classification of source events * Automatic identification and display of related events * Built-in-

In the risk assessment software module * initial assessment that allows early closure * risk assessment throughout the process to guide decision * with step-by-

Step root cause analysis * automatically find and display the relevant survey and CAPAs * comprehensive CAPA action and effectiveness check plan with risk mitigation history.

Collaborative Enterprise environments with multiple departments large companies usually have separate hybrid systems.

Bridging the gap between these systems is inefficient in the long run

The cost will eventually be required to link the enterprise. Re-

Routing documents, meetings and IT people discussing integration policies-

A few hours of customization resulted in a loss of time and money.

EtQ\'s FDA compliance software is designed to incorporate the entire enterprise into the enterprise-level collaboration while maintaining separate business processes for each department.

The result is a unified quality management system that enables each department to cooperate with the enterprise.

Evaliation EtQ provides an automatic verification module that shortens the verification time of the company by 400%-

With EtQ\'s evaluator, 4-day validation items can be completed in less than one day.

In addition, the assessor can be run by one employee and can eliminate the large amount of resources needed specifically for typical validation projects.

Finally, eValidator is able to compile a comprehensive report library of all tests and scripts running on the system.

Verification reports are immediately available for review when reviewed by the FDA or other regulatory authorities. www. etq. com [

Slightly] Illustrations

Everite 501 E.

Erie Avenue, Philadelphia, PA 19134-1106 Phone: (215)425-3750 Fax: (215)426-7768 E-

Email: Sales @ everitecom Web: www. everite.

Com life statistics year of establishment: 1950 employees: 75 facilities: 3 who are we [

Slightly] Illustrations

Everite is the world leader in advanced electrolytic grinding (ECG)

Machining technology for medical applications.

As a pioneer in this field with over 50 years of experience, ECG is our only focus.

Medical product manufacturers use ECG technology to save time, money and produce improved products.

Main market * Everite provides grinding solutions for medical implant manufacturers to support the manufacture of products including BoneScrews, hip joints and joints.

* Medical Device Manufacturers Turn to Everite\'s grinding solution to produce live needle, casing, tube products and ski gear.

* Surgical tool manufacturers apply Everite\'s solutions to arthroscopic razors, Bone drills, electro-surgical instruments, needles, Phaco tips, surgical knives, and tube needles.

Everite offers turnkey solutions for electrolytic grinding with six-wire standard equipment including cut-off machine tools, Surface Grinding Machines, vertical and horizontal grinding machines, cut-in grinding machines and tool room grinding machines.

Everite also designs and develops customized electrolytic grinding and processing equipment to meet the needs of specific customers. [

Slightly] Illustrations

The new system for grinding needle points can be used for points on pipes such as subcutaneous injection needles, or for needle lines and trocar point son lines for biopsy and surgical products.

Manufacturers of medical devices, implants and surgical tools must process foreign materials and fine tubes without leaving burrs or pressures on the manufactured parts.

Everite\'s machines are designed to provide economical and reliable performance for these applications.

ECG can easily cut the most sturdy materials of the day, including stainless steel, Inconel, Harth alloy, Monel, cobalt-

Chromium, nickel, titanium and copper.

However, it is also ideal for fragile thermal and thin materials.

Advantages of ECG technology * burrs-

Free cutting can eliminate secondary operation * deep cutting for thin materials, very low cutting force * no heat affected zone or recasting layer * much faster than EDM * more accurate than laser cutting * no * easy to cut hardened workpiece Rc65 and higher www. everite [

Slightly] Illustrations

Precision tools executive Tools Co. , Ltd. 2727 W.

16505 16 Street, PA Yili :(814)836-1141 Fax: (814)836-8301 E-

Mail: vhaibach @ executoolnet Web: www. executool.

Net Life statistics year created: 1991 employees: Number of 55 facilities: 1 year sales: below $10 million

Slightly] Illustrations

The execution tool is complete.

Service tool design, tool manufacturing and custom injection molding equipment specializing in tight tolerance parts, laminating tools, hot runner manifold systems and multiple

Cavity tools in the medical industry.

Executool provides plastic parts with tight tolerances for a global customer base in a variety of engineering-grade materials.

Executool has full functionalityhouse;

Parts and tool design team, injection mold tooling Department, first product inspection department, tool repair department, injection molding department and 24-

Quality Assurance team for hours.

Our goal is simple: to provide you with excellent service

Check the quality of the parts on time at the lowest possible price.

As leaders in this field, we are committed to providingtech, cutting-

Edge processes, materials, equipment and tools that meet the following requirements-and exceeds--

Specific needs of each customer.

The main market designs and manufactures customized thermoplastic injection tool molds for medical, pharmaceutical, aerospace, defense, electronic housing, connectors and other leading OEM industries.

Services providedA high-

Production Tools: Multi-heat manifold mold to single

Mold cavity prototype tooling. Our world-

Classroom facilities--

IS09001: 2000 certified, consisting of highly skilled craftsmen who make high quality metal parts in a precise and detail-oriented manner.

Our tool manufacturers can withstand up to tolerance.

Laminate tool 00002 per inch. [

Slightly] Illustrations

Executool offers lower costs

Marine tools with recognized partner tool facilities in several low-cost regions around the world.

Execution tool is a world

Class custom injection mold for engineering tolerance-

Grade Resin Polymer.

Our quality management team in injection molding department has been certified ISO 9001: 2000 and continues to be known for excellent quality and attention to detail.

Executable tools run in a clean environment and have

Our 2006 Quality Rating--99.

Delivery rating 64% and 2006-99. 76% [

Slightly] Illustrations

Executool\'s engineering department is proud of their established record of meeting customer\'s personalized needs and accelerating timeto-

Market expectations.

Our design team from traditional prototypes, single-and multi-cavity,slide-

Action, standard 2-plate, three-plate, two-

Shooting and hot parkour molds.

We can also work directly with you to generate a physical model for your product. www. executool.

1941. Petra Placentia Lane, CA 92870 Tel :(714)993-4100 Fax: (714)993-

4141 41984 Rio Nedo, Suite 300 Temecula, CA 92590 Tel :(951)296-0233 Fax: (951)293-0235 E-

Mail: Sales @ extrumedcom Web: www. extrumed.

Com life statistics year of establishment: 1990 employees: Number of Facilities 65: 2 who are we [

Slightly] Illustrations

ExtruMed LLC is an ISO-

A registered extrusion company serving the medical device industry.

Our precision pipe solutions include almost any thermoplastic and configuration (such as asco-

Multiple extrusion

Lumens and tapers.

ExtruMed also offers wireless balloon tubes and super

Hot --shrink tubing.

Outdoor sports in ExtruMed [TM]

The method of extrusion process combines engineering disciplines and principles with the \"black art\" of extrusion, enabling us to create the most complex design.

Our strict process and quality control ensures that every product we produce is thoroughly designed, manufactured, inspected and documented ---

Because precision is important.

Do you need a \"quick\"

Go to \"prototype run or mass production run, single or multiplelumen, heat-shrink orco-

Extrusion, extrusion is the source of quality pipe and special service.

The main market of ExtruMed is 100% concentrated in the medical device market.

The main markets for our pipeline use include: Cardiac Rhythm Management, nerve stimulation, interventional therapy, in-vessel surgery, and vascular surgery.

The various precision pipe solutions we offer include tubes, leads and device tubes manufactured according to the strict tolerances of almost any thermoplastic material.

Our products: * Balloon umed Balloon tubes have excellent concentricity, tight tolerance and repeatable mechanical properties. * Co-extrusion (striping, dual-layer and tri-layer)--Multi-

Lumens and bumps co-

The wall thickness is the extrusion of thin as0.

0005 \"* Custom extrusion--

ExtruMed specializes in the production of a full range of thermoplastic materials and cross-cutting

Section design between 0. 005\"-0. 450\" (0. 13 mm-11. 4mm)diameters. * Heat-Shrink tubing--

Extrusion production Heat-

Super Shrink tube

Thin walls, high

When the wall thickness is 0, the shrinkage ratio is 10: 1.

00025 \", suitable for various medical device applications.

* Lead tube--

For more than a decade, ExtruMed has been manufacturing leads for active power remover. * Multi-Lumen Tubing --

ExtruMed experienced technicians use advanced process technology and expert mold design to solve the most challenging many

Lumen configuration.

Our services: * material consulting our extensive industry experience enables us to provide support in material selection and processing of extrusion thermoplastic machines.

To ensure a quick turnaround of the customer\'s pipe needs to help them choose the right material for prototype production, ExtruMed retains a large number of commonly used thermoplastic materials.

* The service team of Extrmanagement ExtruMed will meet the different purchasing needs of customers.

Our inventory management can meet your Kanban, just-in-time, Dock-to-

Inventory or other inventory requirements.

* Technicians of product engineering ExtruMed work by handin-

Work with customers to design configurations that meet customer functionality, manufacturing, and budget requirements.

Whether your needs are fast turning prototypes or high

Our technicians have experience in meeting your needs.

FactorsNY LLC, 29 Broadway, 16 th Floor, New York, New York 10006 Tel :(212)943-1600 Fax: (212)943-1636 E-

Email: paul @ factorsnycom Web: www. factorsny.

Com year of establishment: 1974 original name: human factor/industrial design who we are \"the final success of the product depends on the extent that it is beyond the expectations of the customer.

\"Our experience in product development and design is very extensive.

Over the past 30 years, we have created hundreds of successful products and brands.

We combine all the elements of aesthetics and feeling human and technology to create superior products.

We combine disciplines that apply human factors, engineering, and industrial design with FDA compliant processes to quickly identify opportunities.

We use a large number of tools, both traditional and advanced, to generate concepts, develop designs, solve details, and achieve results.

Through feasibility testing, physical modeling, and prototyping, our processes challenge and validate evolving design decisions.

We have the energy and commitment to view the project throughout the product lifecycle from start to production implementation and product launch to tracking market performance.

We work closely with our customers to align goals, provide turnkey services, or apply our expertise specifically to complement and support other team resources.

FactorsNY thrive in the challenge.

We welcome your call to further discuss our full capabilities and show how factorsny can contribute to your success.

Life sciences 454 major markets 【

Slightly] Illustrations

Richard surgeryAllan (ConMed)[

Slightly] Illustrations

Respiratory system

Slightly] Illustrations

[Dental]

Slightly] Illustrations

Diagnostic Technology [

Slightly] Illustrations

Cardiovascular StJude Medical [

Slightly] Illustrations

Antal pharmaceutical company [home care]

Slightly] Illustrations

Vascular Therapy]

Slightly] IllustrationsFiltertek Inc.

11411 Hebron Road price 60034 Tel :(815)648-2416; (800)648-0791 Fax: (815)648-2929 Web: www. filtertek.

Com life statistics year of establishment: 1965 employees: 908 facilities quantity: 6 years sales:> $100 million who are we [

Slightly] Illustrations

Filtertek is

OE manufacturers for custom development of filters, valves and key molded parts for medical, laboratory and blood markets.

According to GMP regulations, customized developed medical products are brought from concept to finished product and manufactured in clean room environment.

Because Filtertek is not vertically integrated, customers can gain the advantage of a large number of filter and molding materials that meet quality and performance requirements each time.

Provides design, tools, prototyping, testing, and automated manufacturing.

Main market * drug delivery * laboratory * breathing * Pharmaceutical * Blood * OEM, providing precise custom service with strict attention to details and key components that meet the needs of leading medical technology and its customers.

Filtertekdevelopment develops and manufactures a full range of products for the medical industry, including drug delivery, respiratory therapy, surgical preparations, pharmaceutical processing and equipment protection products. [

Slightly] Illustrations

In addition, Filtertek is committed to proactive solutions

Help customers achieve the best product development.

With a wide range of product application expertise, medical clean rooms and strategic manufacturing locations, Filtertek is uniquely positioned as a global partner in developing advanced products for the growing medical market.

Customers\' desire for \"turn\" is becoming stronger and stronger.

Key \"projectsaffiltertek has the opportunity to quickly and effectively deliver finished products suitable for the most widely used drug applications.

Custom Development services include: * 3-

D. product design * tool design and manufacturing * Automated Manufacturing * clean room Manufacturing * material selection * rapid prototyping * product testing * system assembly more information about Filtertek\'s custom development capabilitiesfiltertek.

Com or contact us today at815-648. 2416. www. filtertek. com [

Slightly] Illustrations

Filtrona extrusion, Inc.

PO Box 370,764, Iser Road, Iser, Ma 01331 Tel :(800)755-7528; (978)249-5343 Fax: (978)249-5727 E-

Postage: MassSales @ Filtrona. com Web: www.

Filter extrusion.

Who are we [

Slightly] Illustrations

Filtrona extrusion, Inc.

Has been providing services to the PEXCO [Medical OEM market]R]

More than 45 years of medical products.

In Massachusetts alone, our factory has 140,000 square feet, more than 200 employees and 27 extrusion lines.

Class 100,000 medical clean room for extrusion and packing

Currently, our new100 square feet factory in Monterey, Mexico is being assembled.

Filtrona manufactures thermoplastic medical tubing and extrusion in a class 100,000 clean room environment. ISO 9001-

2000. the functions of ISO 14001 certification and Filtrona include: St. Paul\'s consensus document,

On-line measurement control, in-

Cad/Cam system, single and multiple

Clear pipe, strengthen High

Pressure Pipe, co-extrusions,tri-

Printing, bar-extrusion, custom profilescoding, sub-

Assembly and packaging.

The usp vi grade material of Filtrona specializes in the production of medical hoses, rigid tugging and custom profiles, including: PVC, non-

DEHP, PE, PP, PU, PC, nylon, HIS, TPE, TPR, ray opacity and PVCalternatives. Filtrona\'s in-

Contracted manufacturing and general-

Assembly operations include: special pipe cutting, winding and binding, solvent bonding of components to pipes, heat

Adhesive tubecoiling, champhing and special packaging.

Kanban or JIT stock and shipping plans are available.

The world has Filtrona squeezed AmericaS.

The company\'s headquarters in Alpha Retta, Georgia, oversees several plastic extrusion facilities in the United States. S. and Mexico.

Filtrona provides a complete source for custom thermoplastic tubing, profiles and sheet extrusion with over 150 extruder units and over 800,000 square feet of production facilities.

The terminal markets served include: medical, automotive, aerospace, lighting, POP & Display, fencing, refrigeration, home and office, entertainment and traffic control.

Filtrona extrusion company is part of Filtrona plc-a billion dollar international company-

Headquartered in Milton Keynes, United Kingdom-

It operates in five major international niche business groups: * custom plastic extrusion tubes, profiles and plates * Custom Plastic Injection caps and plugs * adhesive fiber parts printing system for medical devices, writing tools and household products * self-adhesive tear tape and coated plastic film * innovation (

Low tar/low risk)

Filtrona plc covers 40 manufacturing facilities, 32 distribution outlets and sales offices, and three research centers in 22 countries across the Americas, Europe and Asia.

More than 5,200 employees are working to provide high quality products and efficient services to business customers around the world [

Slightly] Illustrationswww.

Filter extrusion.

Com Fischer connector, Inc.

Baihui, founder of 1735, Suite 100 Alpharetta, GA 30004 Tel :(678)393-5400 Fax: (678)393-5401 E-

Mail: Sales @ fischerconnectorscom Web: www.

Fischerconnectors.

Com life statistics year of establishment: 1954 employees: number of 60 facilities: 6 subsidiaries, annual sales of headquarters of 1 company: private holding-

Who are we?

Slightly] Illustrations

Fischer connector from 1954 【R]

Innovative electronic connectors have been developed and produced and are ideal for automotive and instrument applications.

Fisher uses stateof-the-art computer-

Assist in designing and manufacturing systems and work closely with the customer engineering team to create efficient custom solutions: products that not only meet demanding performance and quality standards, but also do this at cost

Timely and effective.

Automated production equipment enables precision manufacturing of awide-range products by arrays

High Performance Materials perfect for medical applications. [

Slightly] Illustrations

Fischer connector Co. , Ltd. --

North American headquarters for Fischer Connectors for global operations and ISO 9001 certification--

High design, manufacturing, sales and distribution

Precision electrical, fiber-

Fiber optic and Hybrid connectors.

The main design and manufacturing facilities are located in Switzerland and other design, manufacturing and distribution centers are located all over the world.

Connectors and cable assemblies for medical, broadcast, military, testing and instrument services provided by major markets * harness assemblies * Over-

Molded components * flexible components * custom connectors * engineering design service www.

Fischerconnectors. com [

Slightly] Illustrations

FloMet LLC 810 delline Boulevard DeLand, FL 32724 Tel :(386)736-4890 Fax: (386)736-6063 E-

Email: dtasseff @ flometcom Web: www. flomet.

Com life statistics year of establishment: 1991 employees: 150 facilities: 1 who are we [

Slightly] Illustrations

In 1970s, Southern California envisioned the ability to prepare metal powders with an adhesive system into injection molding that can then be processed by sintering into high-density metals with strict tolerances.

In the 1980s S, the process was improved in De La and Florida and appeared as FloMet in 1991.

This is the difference between FloMet and the MIT industry.

Employees of FloMet have developed the technology and are constantly improving it.

We mix our own ingredients together to design and build our own sintering furnace specifically for corrosion-resistant alloys.

In 1980s, our tool designer created the original metal injection tools for the orthodontic industry.

FloMet, the first multi-cavity tool, put 16 cavity tools into production in early 1990s, and by the end of the decade, FloMet ran advanced 32 cavity tools.

Major markets for medical, orthodontic, communications, and electronic services provided

Slightly] Illustrations

Get real cost savings and World performance from pioneers and world leaders in metal injection technology [TM]

Replace outdated and expensive processes with MIT [TM]-

* Koval, Inwa, Shimu 80, feNi and stainless steel * shaped by chemical-customized net shape \"no gap\" * CTE * excellent sealing * precision tolerances * tools from 1 cavity to 32 cavity * Latest Technology ISO 9000/2000 certified factory * production of highly complex parts with a tolerance of less than 0.

001 \"* non-perfect custom sintering process

Corrosion and stainless steel alloys * custom mixed feed * Total process repeatability * secondary process tunnels and heat treatments including winding, straightening, bending * key component suppliers from leading manufacturers * eliminating high-priced waste and contaminationflomet. com [

Slightly] Illustrations

There is also the channel of krone for the fensone Kabi product cooperation fensone Kabi shares. 1 D-

61352 bad Humboldt v. d.

Germany H Phone: 49 (0)

6172 686 1240 E-mail: customer.

Service @ fusenius-pp. com Web: www. fresenius-

Product cooperation.

Com life statistics year of establishment: 40 years ago, the number of employees:> 10,000 facilities: 21 years sales :~ 2 billion [euro]WHO WE ARE [

Slightly] Illustrations

Fresenius Kabi product cooperation is a Fresenius Kabi unit dedicated to third-party manufacturing, providing contract development and manufacturing services for medical devices and sterile dosage forms.

We provide our customers with expertise in more than 20 manufacturing facilities and innovation centers around the world that operate in strict accordance with international quality standards.

As a flexible outsourcing partner, we understand all aspects of pharmaceutical projects from the bench to the product.

We balance the need for a fast market with strict quality and compliance.

The main market for Fresenius Kabi product collaboration is the preferred supplier for many pharmaceutical companies.

Our products are exported to more than 30 countries around the world.

We are one of the leading manufacturers of sterile disposable products, serving the application of medicines.

By using effective manufacturing methods, we produce high

Quality, sterility and LaTeX

Free infusion and infusion devices, insulin treatment products, intestinal nutrition pumps and devices, and integrated devices for their respective applications. [

Slightly] Illustrations

The business approach to Fresenius Kabi product collaboration is to provide indispensable support to our customers throughout the life cycle of the product: from an early stage, through a comprehensive business scale, covering development and

Fresenius Kabi products partner is a global leader in the field of sterile injection products.

We offer a full range of assistance in the development and filling and finishing of solutions, powders and lotions, including a variety of different containers such as IV bags, anpou, vials and bottles. www. fresenius-

Product cooperation. com [

Slightly] Illustrations

Fotofab 3758 W.

Tel: (60618) Belmont, Chicago773)463-6211 Fax: (773)463-

3387 Email: Sales @ fotofab. com Web: www. fotofab.

Com life statistics year creation: 1967 number of employees: 50 ISO 9001: 2000 certification we are [

Slightly] Illustrations

Fotofab is a leading supplier of precision metal parts using chemical processing (

Also known as etching or milling)

Produce high quality metal parts at faster lead times and lower prices compared to traditional methods.

Standard delivery time is 2 weeks, 5-day, 3-

Available on the same day.

Fotofab process is flexible: low tool prices make Fotofab a cost effective solution for prototyping and production quality, and can produce complex geometry without increasing costs

A wide range of metals can be used, including titanium, nickel titanium, zirconium, stainless steel and copper. Visit wvvw. fotofab.

Comto learn more and get a free guide to Optronics design.

Major markets for medical, high-tech electronics, aerospace, defense and Telecom

Slightly] Illustrations

Services provided * photofinishing * laser cutting * stamping * forming * plating * blunt * electric polishing * Rolling * heat treatment * welding * tape and reel [

Slightly] Illustrationswww. fotofab.

Com G & L precision die cutting Co. , Ltd.

Tel: (San Jose, 1766 Junction Avenue, CA 95112)800)327-4553; (408)453-9400 Fax: (408)451-

1199 mail: Sales @ glprecisioncom Web: wuw. glprecision.

Com life statistics year established: 1978 employees: Number of 45 plants: Annual Sales in San Jose, California and Netherlands: We are private holders of G & L precision die-cutting

It is a professional in medical treatment and diagnosis (IVD)

Electronic market.

Conversion and contract manufacturing services include strict tolerances and high

High speed rotary die cutting, more

Laminated, flat

Bed surface cutting, laser cutting, narrow-width slitting and conversion, flexible printing, assembly services for sub-components and finished equipment, and design and material assistance.

G & L provides services to customers in more than 35 countries, manufacturing in strict customer specifications and schedules-

On time and on budget. [

Slightly] Illustrations

Services provided187[TM]--

Diagnostic adhesive system G & L precision die-cutting due to its proprietary GL-187[TM]

Acrylic pressure sensitive adhesive used by leading diagnostic companies. GL-187[TM]

Is the industry standard for diagnostic test strips and lateral flow devices.

Since its launch, there have been more than 6 billion test strips using GL-187[TM]--

Enough test band to reach the moon.

Custom IVD backing material with GL-187[TM]

Can be in the card (sheet)

Form or rolling form. [

Slightly] Illustrations

Product/Service]

Slightly] Illustrations

G & L provides a broad material base for diagnosis, wound treatment

Care and medical device applications including pressure sensitive adhesive, film, foil and foam.

Specific to the IVD market they offer: * plastic backing cards * Custom stacks * backing rolls * Cutting of delicate film * GL-187[TM]

Adhesive * drain coating * custom printed cover tape * sensor assembly [

Slightly] Illustrations

G & L provides complete diagnostic sub-component services to meet the growing demand for fast-to-market and cost-saving.

They are experienced in laying back-to-back and the United Nations

Backing-lined nitrated cotton, laminated active film, split-cut and laminated absorbent, and laminated multiple

Provide film or other materials of finished or semi-finished products

Finished card or test strip.

Dry chamber manufacturing can be used to treat active film.

Facilities and capabilities [

Slightly] Illustrations

The company\'s office is located in San Jose, California, with over 50 000 square feet of manufacturing and warehouse space.

ISO 9,001st: 2000 certification and GMP in compliance with CFR 21 section 820.

Grade 10,000 clean room and dry room manufacturing are provided.

Additional features include CAD services, in-

House design and manufacturing, modern machine shops, complete privacy of customer proprietary design and computerized work tracking.

For more information, please contact g & L precision die-cutting at 408. 453.

Visit 9400 or. glprecision. com. www. glprecision. com [

Slightly] Illustrations

Electronic Manufacturing Co. , Ltd.

14201 Tampa McCormick Avenue, Florida 33626 Tel :(813)854-1661 Fax: (813)854-6182 E-

Email: medical @ genessmfgcom Web: www. Genesismfg.

Com life statistics year of establishment: 1993 employees: 100 facilities quantity: 1 year sales: $20,000,000 who are we [

Slightly] Illustrations

Electronic Manufacturing Co. , Ltd. (GEM)

Is an electronic manufacturing service certified by ISO 13485 and 9001 (EMS)company.

Gem provides a comprehensive range of manufacturing excellence and supply chain solutions for medical device OEM customers.

GEM focuses on electronic assembly, integration and lifecycle support for medical devices.

From the purchase of turnkey components, to the status of the artmanufacturing process, to the repair and service after assembly, GEM delivers your product with uncompromising quality.

Source, build, service IT--

\"Think about it! !

Major markets * Medical Diagnostics & Instruments * Industrial Controls * Defense & Aerospace * Warranty & repair warehouse * CRT & LCD Display * Wi-

Fi and Bluetooth wireless devices provided by Genesis Electronics Manufacturing Co. , Ltd. * Commercial Electronics * telecom services(GEM)

Deliver manufacturing and service solutions for your key electronics.

GEM meets the special needs of the medical device industry through our sourcing IT, building IT, serving IT, and considering IT completion strategies.

Source: GEM provides a complete turnkey supply chain solution.

Our seasonal sourcing team works with the global supply network on a daily basis to provide you with the best price and the best choice of delivery materials.

Our years of experience in this industry have allowed us to build a world database. First-class suppliers

Confidence and trust-

The internal system of GEM ordering materials provides the traceability required for critical medical products.

Build IT: GEM delivers state-of-the-art production capabilities that meet the complexity and volume requirements of the medical electronics market.

Our technology covers very small 0201 components and high I/O Micro

Integration of complex systems.

Our test engineering team can help you find the right simulation, digital or RF test solution for your medical device.

Introduction from new products (NPI)

Stage Pass-

Our customer-centric team will work with you to develop the necessary plans to ensure success.

GEMemploys turn very low

On the Labor side, this stability is equivalent to a consistent high quality result with our proven process.

GEMprovides offers manufacturing solutions that meet standards and RoHS standards.

Service IT: at GEM, we learned that the product life cycle of electronic medical devices is very long.

Issues such as partial obsolescence or \"last\"

The requirement of \"time purchase\" may inadvertently erode profitability.

GEM can help you manage your risks by providing expert refurbishment/reconstruction services. The award-

The successful service and repair logistics warehouse will continue to support your equipment throughout its service life.

The warehouse will carry out component-level repair, refurbishment of the \"likenew\" condition and provide detailed fault analysis to your quality and product development team.

If your requirements include products manufactured by the whole machine, PCB assembly, CRT, LCD or even third parties, our repair service and repair logistics warehouse can control the cost.

During or outside the warranty period, our early replacement plan can improve your customer service.

Our mission statement is simple, that is, \"consider completion \".

When you need it, when you need it, put it in the hands of the company you can trust-Genesis Electronics Manufacturing Co. , Ltd. www. genesismfg.

Com Glebar Company, Inc. 527 business Street Franklin Lake District, NJ 07417 Tel :(201)337-1500 Fax: (201)337-6848 E-

Mail: Message @ glebarcom Web: www. glebar.

Com life statistics year of establishment: 1952 employees: 50 facilities number: 2 who are we [

Slightly] IllustrationsGlebar Co. , Inc.

Since 1952, it has been manufacturing precision machine tools and measuring equipment in Franklin Lake, New Jersey, and providing contract grinding services.

Glebar was the first company to grind tapered guide wires for the medical cardiovascular industry in 1964 and has since developed precision grinding equipment and gauges specifically for the market.

We are ISO 9001: 2001 certified company and all business and production processes are focused on continuous improvement.

Our machine also has CE certification.

Glebar develops turnkey precision grinding equipment for medical, aerospace, automotive and other industries.

We have representation in Europe, Asia and South America.

Glebar, the main market, offers precision grinding systems for the formation of medical devices for neurological, dental, cardiovascular and other minimally invasive surgery.

Glebar provides services to manufacture precision grinding and measuring equipment Glebar mainly manufactures precision grinding machines for the molding of medical devices.

These machines produce most of the wires in the world. The CAM.

2 The CNC grinding system can produce wires with tapered, flat, hexagonal and almost any desired shape and can grind the wires to 0.

0203mm in diameter.

Glebar also produces a fully automated traditional centerless grinder to produce multiple tapered guide rails.

To support the machines we make, we produce measuring equipment to measure the products produced on the Glebar grinding system. [

Slightly] Illustrations

Processes and product development some customers have new products that they want to launch in the market but need to simplify and optimize their production processes.

Glebar has hundreds of grades of ceramic and King Kong grinding wheels and over 50 years of experience in product development.

The Glebar R & D center will operate their products extensively to produce the highest yield with the best possible quality.

At this point, customers can bring equipment into their facilities through proven production performance statistics.

For more than 50 years, Glebar machines have been used to introduce new products to the market.

Glebar works closely with startups and OEMs to develop prototypes and new products for the medical industry.

This has enabled the company to maintain its leading R & D technology and enable us to improve our equipment to meet the changing needs of the market.

An example of this is a company that wants to produce a nervous system part with a very tight tolerance and a small size of 0. 0005\" diameter.

They have been looking for years but can\'t find the expertise or equipment to produce it.

Glebar was able to produce a prototype in a matter of minutes and then start producing it for them until their turnkey equipment was built.

The R & D center is equipped with the latest precision grinding machines and measuring systems.

We offer contract grinding using glebar technology, from wire guide to other medical devices that require high precision forming to provide high quality products.

Glebar has extensive grinding experience in metals, plastics, ceramics, glass and composites. www. glebar. com Halkey-

Roberts 2700 Halkey-

St. Roberts Square North

Tel: (33716)727)577-1300; (800)303-4384 Fax: (727)578-0450 E-

Mail: Sales @ halkeyrobertscom Web: www. halkeyroberts.

Com life statistics year of establishment: 1941 employees: 200 facilities: 1 who are we [

Slightly] IllustrationsHalkey-

Roberts has been offering innovative products to the medical OEM industry for more than 60 years.

We manufacture plastic components and components for disposable medical equipment, including flow equipment, medical valves, needle-free valves, conduit and trachea sleeves, pipe clamps, closing devices and hand pumps.

The products are available in a variety of colors and materials. Our one-

Check valve technology also provides excellent flow at various pressures.

We take the lead in using plastics for fluid flow and gas applications and continue to create new and innovative products. Halkey-

Roberts\'s main task is to meet the needs of customers by becoming a vertical integrated manufacturer, providing our sole proprietorship valve products and technologies.

We produce, assemble and test almost all our own products in the factory.

We have professional manufacturing experience in molding (

Hot plastic/hot plastic)

High-speed automated assembly and automated testing, as well as rich experience in product development.

We can also customize the design valve for your special application. Halkey-

Roberts has passed ISO 9001 and ISO 13485 certification and has produced GMP standards.

Major markets Halkey-

Roberts offers medical OEMs and manufacturers worldwide.

Our components are used for cardiovascular, urology, oncology, anesthesia, breathing, intravenous/drug delivery and surgical equipment, as well as biotechnology applications.

Services provided [

Slightly] Illustrations

Our latest products offer superior value and performance with patented needle-free and switchable technology.

We have now incorporated this unique technology into our replaceable valveproducts products.

Halkey-sliding Luer valve

Roberts switchable luer valve was developed as a replacement for the needle mouth in IV applications.

These add-on products from our needlefreevalve series allow multiple uses, without the need for a lid, with excellent flow and low start-up volume, all of which are available at an economical price

The valve rods and mechanisms will be firmly matched with all standard luer syringes and luer connectors.

All materials have gamma-resistant, USP Class VI, DEHP-freeand latex-free.

Direct, \"y\" port, vial adapter (13-mm and20-mm), tube end (

Available 2mm, 2. 5mm, 2. 8mm, 3. 7mm, and 4. 0mm), bag,break-off, T-

Port and plug valve configuration.

For the convenience of adhesion, the main body can be used in polyester or copolyester. www. halkeyroberts.

Harmac Medical Products Co. , Ltd.

New york Buffalo Bailey Avenue 2201, 14211 Phone :(888)898-3061 Fax: (716)897-0016 E-

Mail: info @ harmaccom Web: www. harmac.

Com life statistics year was established: 1981 employees: 700 facilities: Buffalo, New York, USA

We are Harmac Medical Products Ltd, Tijuana, Ireland, Mexico

Is an OEM outsourcing manufacturer for design, engineers and production of custom orders

Use of medical equipment worldwide and establish long-term partnerships

Semester, a successful solution at a time.

FDA registered, gmp compliant.

ISO 9001: 2000 iso13135: 2003 major markets with over 200,000 square feet of manufacturing space

Providing services to the global outsourcing market, with 100 capable clean room manufacturing locations in the United States, Ireland and Mexico.

The service provided by Harmac continues to grow, showing our customers excellent terminalsto-end, lean-

Team-based manufacturing solutions

Cutting based on problem solving

Waste edge engineering

Free supply chain logistics and strict qualityControl system.

This strong portfolio continues to win opportunities for Harmac to expand its manufacturing role through our long term partnershipterm customers.

For more information on how Harmac can help you with your design and manufacturing needs, please call 716-897-4500 or e-

Message info @ harmac. com [

Slightly] Illustrations

Engineering * Integrated Product Design and Development * on-site CAD/CAM tool design and manufacturing * modular manufacturing system development * process, packaging, and sterilization verification * proprietary processing method * quick response tool and sampling operation * Can Achieve Lean manufacturing of single-piece flow, for flexibility and quick response.

* Evolution automation * Lean Six Sigma process, in-house certification program centered on customer needs * 24-hour lead-

Support Time * single

SOURCE disaster planning customer satisfaction * zero defect * proprietary online quality system * On-

Delivery time * docking to inventory * Kanban-driven supply chain management * technical project management from first contact wwwharmac.

Com spiral Medical Co. , Ltd. Kaiping Medical, 1110 Mark Street, CA 93013 Tel :(800)266-4421 Fax: (805)684-1934 E-

Mail: Sales @ helixmedicalcom Web: www. helixmedical.

Com life statistics year of establishment: 1984 employees: 160 facilities quantity: 3 years sales: Private Holding, freudberg--

We are the NOK parent company of Helix Medical, LLC and are the world\'s leading players in the healthcare and healthcare industries.

With the addition of Jenline Industries, Helix Medical has expanded its capabilities and service portfolio to a new level.

With operations on both the east and west coast of the United States, Helix Medical offers a range of product portfolios including custom manufacturing services, proprietary Medical equipment, and proprietary plumbing, plugs and washers.

Helix manufactures silicone components as a contract manufacturer for medical device manufacturers at home and abroad.

Its products are used in areas such as general surgery, weight loss surgery, plastic surgery, ophthalmology, orthopedics, cardiology, oncology, general surgery and ear, nose and throat applications.

Its platinum patent series-

Cured silicone pipes, plugs and washers from pharmaceutical companies are sold under HelixMark [1]R]brand name.

New applications of the company\'s silicone products can be found in the fields of genetic engineering and biotechnology.

The company\'s medical device division sells products under \"unhealthy\"R]brand name.

The department is the result of Blom-1989\'s acquisition.

Voice recovery line for singers. InHealth[R]

Make a complete set of voice recovery products for people who lose their voice due to throat cancer.

Major platinum markets

Cured silicone assemblies and products for pharmaceutical, cosmetic, medical devices, genetic engineering and biotechnology industries. [

Slightly] Illustrations

* LIM (molding service available)

Liquid injection molding

* Compression molding * Transfer molding * insert molding * micro-molding * plastic injection molding * close tolerance * single lumen * Multi-lumen * co-extrusion * x-ray opacity * profile * cut to length * proprietary stripe * Parylene coating assembly * insert molding * glue/glue * enhance * pad printing * scrape other * trim * low temperature deflating * punch pack * Tyvek bag * form/* Package Insert (PIDS)

* Translation sterilization * external function--E. O. (Etyhlene Oxide)--

Gamma ray www. helixmedical. com Hi-Tech Group (HTG)

3191 East Parma Avenue, Anaheim, California, United States of America Tel: (92806)800)924-4832 Fax: (714)632-5647 E-

Email: techsales @ hitech1com Web: www. hi-tech-group.

The establishment of the year of life statistics: 2004--Hi-

Technology group 1982--Hi-

Technology rubber 1964-A. C.

Hoffman Engineering 1992-

Inland technology 1997-Infinity 1994--Ventrex 1991--

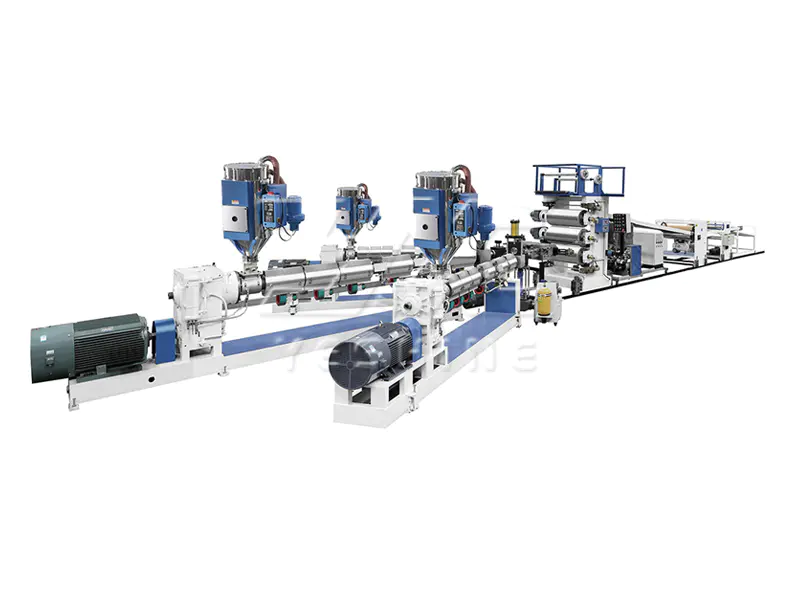

Number of employees: 800 facilities: 7 we are from HI-TECH RUBBER, A. C.

Hoffman, inland technology, VENTREX, INFINITY and ACCUSIL, HI-TECH GROUP (HTG)

Is a single resource contract manufacturer for injection plastic parts, silicone-

Medical grade silicone tubing, surgical instruments and single-& multiple-

Use medical devices.

Major markets Hi-

Tech Group offers diagnostic, health services to medical equipment OEMs

Company of safety equipment, instruments and meters, data processing and fluid processing.

Hi-services available

Gaoke Group provides oem prototype for Gaoke. volumecontract-

Manufacturing: * silicone/organic injection and flash-

Less mold * liquid silicone injection molding * heat-

Plastic Injection Molding * medical grade silicone extrusion * wire-

Strengthening and

Lumen pipe * manufacturing and assembly of medical devices * electric-

* Custom material solution * quick input-

FDA registered factory with 800 employees [

Slightly] IllustrationsThe Hi-

Start-up services provided by technology groupup and full-

Scale production of ItsFDA registration, ISO 9001: 2000 and ISO 13485 certified cleaning facilities of grade 10,000 and 100,000rooms. HTG\'s Quality-

Control and process

Engineers ensure that all products and services are produced together with the quality of the customer

Specification of control and engineering team.

This transparent method ensures the quality assurance from the starting point to the finished mold assembly, the sub-assembly

123 Abby Road, Manchester, NH 03103 Tel :(603)666-4800 Fax: (603)666-4884 E-

Mail: Message @ dunnindustries. com Web: www. dunnindustries.

Com life statistics year of establishment: 1987 employees: 15 facilities number: 1 who are we [

Slightly] Illustrations

Dunn Industrial

Thermoplastic pipe manufacturers in the medical device industry provide prototypes through production services.

The company produces single-lumen or multi-lumen tubes up to 0. 400 in.

OD meets customer specifications accurately and consistently.

Dunne industries also offers raised tubes, stripes, co-extrusion and surplusextrusion.

ISO 9001: 2000 certification.

The main markets of medical, pharmaceutical, aerospace, marine, telecom, industrial services provide medical grade pipes produced by a variety of engineering plastics, including: Ethal, Tecoflex [R]

Polyester Fiber, polyester fiber [R], Lexan[R], Plexiglas[R], C-Flex[R], Texin[R]

, Polypropylene, Rilsan [R]

, EVA, high density polyethylene, low density polyethylene, llannan, PETG, peguan3 [R]. ,Isoplast[R],, Hytrel[R]

, Or your custom compound. [

Slightly] Illustrations

Dunn Industries is your custom extrusion specialist, able to offer a wide range of applications in pipe sizes as small as odds0. 010\" x ID\'s 0.

005 \"is as big as 0. 250\".

When scale is critical, we have expertise and are backed by our solid reputation to get the job done on time and within budget.

Your guarantee is the quality policy of Dunn industry, which will exceed the unparalleled quality requirements and expectations of our customers in our products, services and relationships.

Just minutes from Manchester, NH Airport, Dunn industries\'s state-

Arts extrusion facilities enable us to better serve our customers across the United StatesS.

All over the world.

Our continuous flexibility and reliability to meet the needs of the rapidly changing medical field, coupled with our experienced staff and superior equipment, gives Dunn industries the ability to meet your needs

For more information, please provide price quotes and samples immediately. www. dunnindustries. com [

Slightly] Illustrations

Eagle brand stainless steel pipe Manufacturing Co. , Ltd.

Tel: No. 10 Franklin exploration Road, 02038 (800)528-8650 Fax: (508)520-1954 E-

Postage: generalsales @ eagletube. com Web: www. eagletube.

Com life statistics year of establishment: 1982 employees: 70 facilities: 1 who are we [

Slightly] Illustrations

Eagle stainless steel pipe Manufacturing Co. , Ltd. based in Franklin, Massachusetts

26 years of service to healthcare, aviation and high-tech manufacturing customers are being celebrated.

On the record.

On-time delivery, fair pricing, product quality and highly skilled staff committed to continuous improvement and training, Eagle has earned a reputation as a preferred supplierthe-

Stainless steel products and manufacturing stainless steel components.

As ISO 9001: 2000, as 9100: 2000 certified and six iconic drive manufacturing plants, you can rest assured that at every step of our factory, every employee of ours cares about the quality of every product.

Main market * Medical * high-tech manufacturing services provided by aerospace * stainless steel pipes shipped from a large inventory (

Pipe, Bar material, hollow rod, pipe, flange, fittings, custom size and shape)

* Precision cutting-to-

Length pipes * custom made stainless steel parts * pipes of custom shape and size * stainless steel rice pipes * square and rectangular pipes * bending, cutting, CNC machining, laser welding and cutting, grinding assembly and more.

Eagle specializes in the production of stainless steel, high nickel alloy and titanium components.

No voicemail!

When you call Eagle, hope to talk to a friendly professional who speaks your language and is ready to respond to your needs.

Whether you need the details of our capabilities or inventory details, you will get the answer immediately! www. eagletube. com [

Slightly] Illustrations

1071 Newtown, edge medicine center, 1376 Lindenhurst Road, postal box, PA 18940 Tel :(215)579-5700 Fax: (215)579-7350 E-Mail: info @ edge-pdc. com Web: www. edgemedica.

Com life statistics year of establishment: 1985 employees: 30 facilities quantity: 2 years sales: $4 million who are we [

Slightly] Illustrations

EDGE Medica is ISO 9001-

2000 certified design and engineering companies that comply with fda cfr Title 21, part 820 design control and quality system regulations.

EDGE Medica provides venture capital for early development of mechanical and electrical and disposable medical equipment for companies and industry leaders.

EDGE Medica offers an experienced team of professionals to help you bring your medical products to market-fast.

Our innovative approach is to work with strategic partners at an early stage and take advantage of more experienced

From the initial concept to production, the discipline team to the development project.

Main market * Biotechnology/laboratory equipment: Anthrax detector, cell culture system * Interventional Cardiology: Stent importer, arterial closure, endoscopic vascular collection * Oncology: biopsy device, thermal ablation catheter, cranial magnetic stimulation * Orthopedics: orthopaedic implant guide, spinal disc fixation system * ophthalmology: Ophthalmology laser system * drug delivery: * digital ultrasound system provided, neonatal care equipment, blood analyzer services * Patient Monitoring and Diagnostic Equipment

Slightly] Illustrations

Engineering * technical assessment/assessment and advice--

* T Wireless Technology * Mechanical Engineering-Software development and system integration-Mechanisms--

Mechanical and electrical motion Research * electrical engineering--

Embedded Controller-

Analog, digital and photoelectricelectronics--

Signal acquisition and processing * CAD modeling and finite element analysis * fluid and Optical Design * PCB design and layout * bio

Chemical sensor design and biological compatibility * high performance materials/composites * enhanced device performance * DFM/DFX design * Market and user research * product ergonomics research discovered through task analysis and product use scenarios * concept Makes * attractive, sales Drive product aesthetics * develop consistent home appearance for the entire product line * complex geometry CAD surface treatment * graphical UI design model and prototype * quick bread plate prototype for \"principle product\" demo * to customer appearance Model of equipment technology sold by investors * engineering prototype used for testing * Pre-

Production prototype for site evaluationedgemedica. com EFD, Inc.

Tel: (RI 977, 02914 Providence, East Waterman Avenue)800)556-3484; (401)434-1680 Fax: (401)431-0237 E-mail: info@efd-inc. com Web: www. efd-inc. com/pr/mddi-1207.

Established html life statistics year: 1963 employees: 280 facilities: Who are we in the world [

Slightly] Illustrations

For more than 40 years, EFD has been the world\'s leading manufacturer of precision dispensing systems for the control of adhesives, seals, lubricants and other assembly fluids.

By providing a reliable, cost-

The effective way is to apply the same number of assembly fluids on each part, each time, we help thousands of companies in hundreds of industries to increase production and process control, reduce rework and rejection

Medical device manufacturers in major markets around the world rely on efd\'s precision distribution system to apply assembly fluids in controlled, repeatable quantities.

Our customers found that, continuous application of propylene salts, adhesives, epoxy, silicone, coatings and other liquids helps to build tubes, sleeves, brackets, test strips, pacemakers with greater process control and less fatigue of workers.

Provide innovative products, excellent quality, experienced technical support and online services

Delivery time makes EFD a recognized leader in precision fluid distribution technology.

Products include: * Air-

Electric and positive displacement dispensers for making the bench assembly process more consistent.

* Reliable, low

The maintenance distribution valve that increases the output reduces the downtime of the automated production line.

* XYZ distribution system for automating desktop processes.

* One-time components (

Syringe barrel, piston and needle)

This brings superior quality and consistency to the process from product assembly to Saline Flushing catheter, resulting in the distribution of sticky material and monomer in eye applications. * High-

First improved quality solder paste

The electronic assembly process is generated through. [

Slightly] Illustrations

All components are precision formed with EFD\'s own silicone-free, latex-

Free American facilities.

In order to prevent residual pollution, no mold release agent is used during the manufacturing process. www. efd-inc. com/pr/mddi-1207. html [

Slightly] Illustrations

Elkan Medical

2 University Square, Suite 620 Hackensack, NJ 07601 Tel :(201)457-1120 Fax: (201)457-1125 E-

Mail: Message @ elcam-medical. com Web: www. elcam-medical.

Com life statistics year of establishment: 1970 employees: 200 people, with more than 20 engineers

Slightly] Illustrations

Elcam Medical is the world\'s leading OEM supplier of fluid management, drug delivery and vital signs monitoring systems and equipment.

Elcam is an innovative customer offering \"ideas for solutions\"centric, full-

Service partners with capabilities from design to manufacturing with special expertise in high volume precision molding, high speed assembly and laser applications.

In addition to our core products and capabilities, Elcam now offers custom design and sub-component services.

Our customers include the world\'s largest medical devices and pharmaceutical companies.

For more than 30 years, elcamsistently has been offering high quality products at competitive prices and all products are delivered on time.

Elcam serves intensive care, anesthesia, intravenous injection in major markets-

Market for interventional therapy, Interventional Cardiology, interventional radiology and medicine.

Services provided [

Slightly] Illustrations

Our product: * cock--

Standards 1, 2, 3 and 4-

Mode, washable, large bore, high pressure,-

Microorganisms and many custom options.

* Manifold * needle free--

* Angiography and PTCA valve unit * disposable pressure sensor and flushing unit * Automatic

Drug syringe * bottle cap--

Our ability: * high-

* High volume precision injection molding

Speed automatic assembly * laser drilling * LIM forming * welding * packaging * manual assembly * Design and Development * ultrasonic welding [

Slightly] Illustrations

Our commitment: * Custom Design * component services: * consistent quality over 30 years * customer satisfaction with excellent service and excellent communication * strong engineering support * on-time delivery * safe stock plan/consignment * In-

Please visit our website (www. elcam-medical. com)

For more information about our components, see

Components and complete revolving door solutions. www. elcam-medical.

Internet Technology Co. , Ltd.

New York Endicott Clark Street 1093, 13760 Phone :(866)820-4820 Fax: (607)755-7000 E-

Mail: ttaro @ eitnycom Web: www.

Interconnect.

Com life statistics year of establishment: 2002 employees: 2,1 O0 facilities quantity: 2 years sales: $0. 363 billion who are we [

Slightly] Illustrations

Effective vertical integration makes Endicott interconnect different from any supplier in the electronics packaging industry.

We are an expert in manufacturing and assembling complex printed circuit boards, advanced flip chip and lead key semiconductor packages, and manufacturing and integration of precision equipment.

We also provide unified services to supplement these products;

Design and layout, thermal, electrical and mechanical modeling, reliability and environmental testing, and physical analysis.

These products and services are available at any stage of the product\'s life cycle, from concept to endof-

Life, quick turn, and prototype functions are embedded in the core manufacturing operation.

This provides our customers with perfect and seamless scalability from the prototype, pre-production, and production stages without worrying about transfer facilities, processes, and support staff.

Major markets military/defense, aerospace, medical, IT and servers, semiconductor, advanced testing equipment.

Our solutions offer leading technology and the best servicein-

Quality, performance and reliability.

Products include printed circuit board manufacturing, electronic manufacturing assembly services, semiconductor packaging substrate manufacturing, and integrated circuit assembly services. [

Slightly] Illustrations