cnc router or saw - a debate among north american woodworkers

by:YESHINE

2020-06-10

Shop owners in the woodworking industry are debating which machine is a better choice: a CNC router or panel. The answer is . . . it depends. Read on.

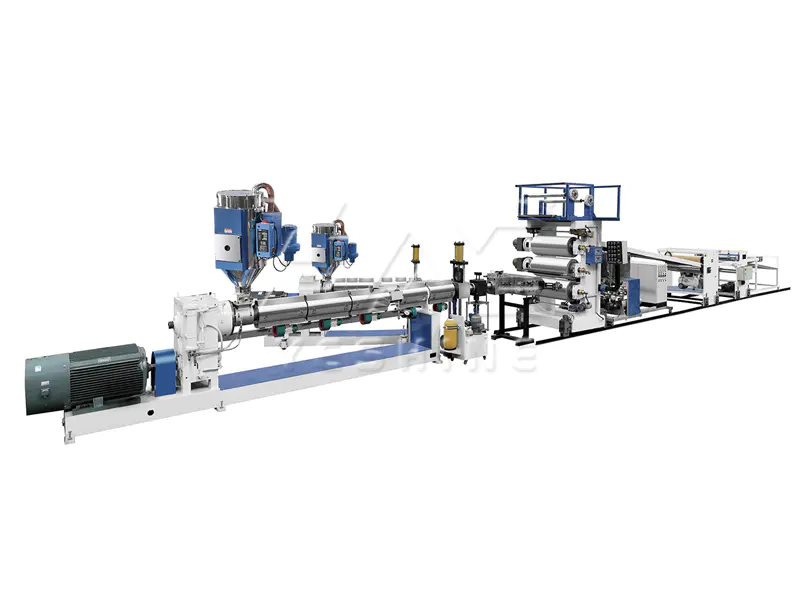

The CNC router is a flat panel router used to shape solid or man-made boards.

They can also make all kinds of parts from sheets made of wood and wood

Composite, plastic or nonferrous metals.

This process is called nesting, optimizing the optimal yield of panel sizes from larger plates.

The sheets are fixed on the table by means of a fixture or suction with a mechanical fixture.

Routers typically have one or two worksheets running up to four router heads at the same time.

They are computers.

Control operation along 2 to 5 axes (

3 axis is the most common).

Most CNC routers also drill holes if needed.

The panel saw (or beam saw)

Is a machine that makes straight cuts (

Or guillotine)

On plates of wood, plastic, phenol and non-woodferrous metal.

Panel saws are most commonly used for cutting wood

Basic materials such as plywood, scrap board, medium density fiber, OSB and high density fiber

Density fiber sheet.

The panel saw can be configured to manually load a single sheet of paper, loading one or more sheets from the lift table.

They can cut a single sheet with a thickness of up to 3mm and a depth of up to 8 \".

Let\'s first look at the advantages of a CNC router over a panel saw.

The CNC router is essentially a more versatile machine.

It can cut straight edges like a panel saw, but it can also combine cutting with cutting: So if your store needs to operate multiple times, a machine can do almost all of it, thuslabor! ).

In addition, the machine is able to get more output from the paper, because it can do certain cuts that the panel saw cannot do at all.

Now, let\'s take a look at what advantages the panel saw has on the router.

It\'s easier for them to learn and work in programming (

Because their operations are much more complicated).

The saw can cut the stacked paper, thus producing a higher quantity in a short period of time.

This allows other machines to use parts in subsequent processes (

Splitting, drilling, wiring, etc. ).

So select the panel saw if you need a lot of the same parts.

If you do a lot

Then select the CNC router to select multiple different sizes in a low quantity.

The intersection is between 20 and 100 parts of each unique size.

If production is more important than time, the CNC router may be better.

Alternatively, use the panel to view if time and throughput are the most critical.

In either case, software is the key to 1.

Make your programmers and operators comfortable

Optimize the use of materials.

Make sure your machine control and production planning software is working properlyto-date.

Fortunately for those who buy extra machinery in the market, there are a lot of cheap used machines.

When it comes to choosing the right stand-alone machine for your store, or, as mentioned above, decide the most important aspect of your business.

The CNC router is a flat panel router used to shape solid or man-made boards.

They can also make all kinds of parts from sheets made of wood and wood

Composite, plastic or nonferrous metals.

This process is called nesting, optimizing the optimal yield of panel sizes from larger plates.

The sheets are fixed on the table by means of a fixture or suction with a mechanical fixture.

Routers typically have one or two worksheets running up to four router heads at the same time.

They are computers.

Control operation along 2 to 5 axes (

3 axis is the most common).

Most CNC routers also drill holes if needed.

The panel saw (or beam saw)

Is a machine that makes straight cuts (

Or guillotine)

On plates of wood, plastic, phenol and non-woodferrous metal.

Panel saws are most commonly used for cutting wood

Basic materials such as plywood, scrap board, medium density fiber, OSB and high density fiber

Density fiber sheet.

The panel saw can be configured to manually load a single sheet of paper, loading one or more sheets from the lift table.

They can cut a single sheet with a thickness of up to 3mm and a depth of up to 8 \".

Let\'s first look at the advantages of a CNC router over a panel saw.

The CNC router is essentially a more versatile machine.

It can cut straight edges like a panel saw, but it can also combine cutting with cutting: So if your store needs to operate multiple times, a machine can do almost all of it, thuslabor! ).

In addition, the machine is able to get more output from the paper, because it can do certain cuts that the panel saw cannot do at all.

Now, let\'s take a look at what advantages the panel saw has on the router.

It\'s easier for them to learn and work in programming (

Because their operations are much more complicated).

The saw can cut the stacked paper, thus producing a higher quantity in a short period of time.

This allows other machines to use parts in subsequent processes (

Splitting, drilling, wiring, etc. ).

So select the panel saw if you need a lot of the same parts.

If you do a lot

Then select the CNC router to select multiple different sizes in a low quantity.

The intersection is between 20 and 100 parts of each unique size.

If production is more important than time, the CNC router may be better.

Alternatively, use the panel to view if time and throughput are the most critical.

In either case, software is the key to 1.

Make your programmers and operators comfortable

Optimize the use of materials.

Make sure your machine control and production planning software is working properlyto-date.

Fortunately for those who buy extra machinery in the market, there are a lot of cheap used machines.

When it comes to choosing the right stand-alone machine for your store, or, as mentioned above, decide the most important aspect of your business.

Custom message