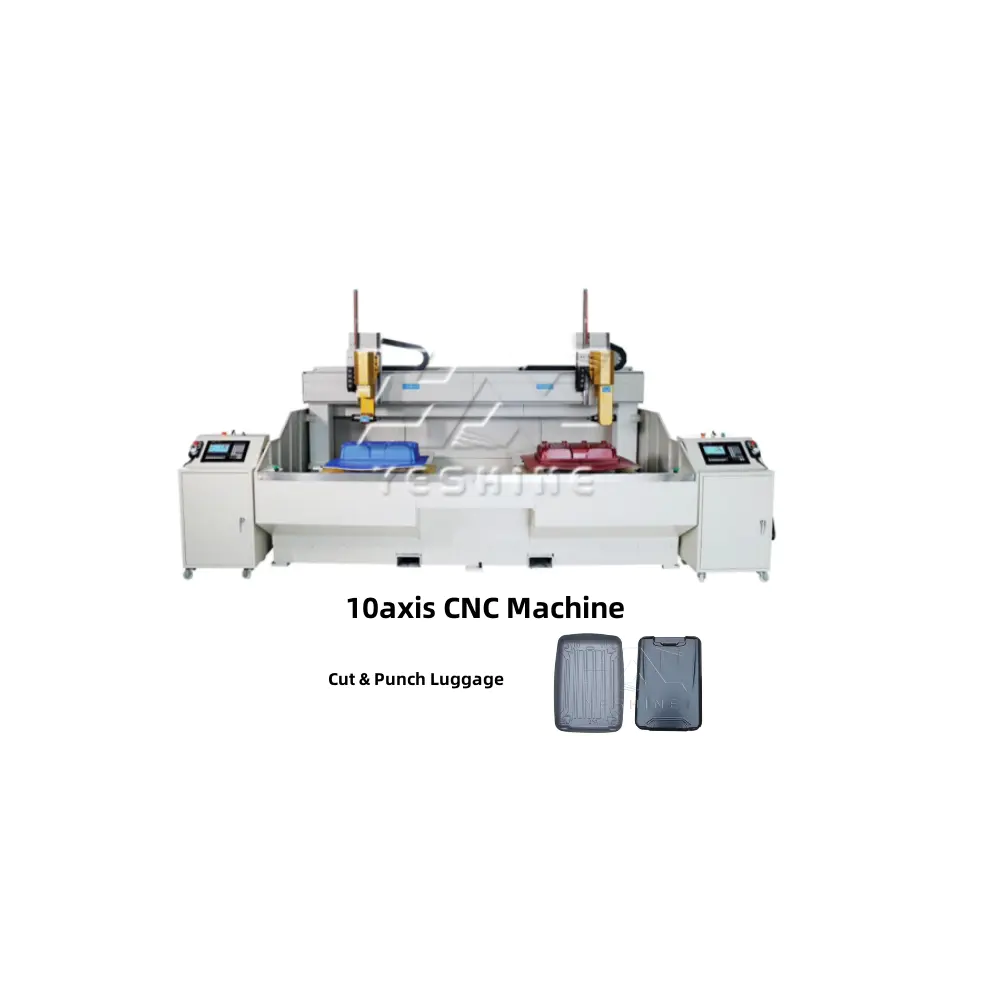

Automated luggage making machinery

by:YESHINE

2020-10-10

At present, automated luggage making machinery has developed to a fairly mature stage. Automation is a high-tech company specializing in the research and development, production and sales of intelligent automatic control, digitization, and networked controllers and sensors. Its numerous functional modules and complete embedded The solution can best meet the individual needs of many users. The company's products have a variety of series of products to meet customer needs. The luggage machinery is composed of a vibrating plate.

Common fault detection

Any automated luggage making machinery is composed of three parts: actuators, sensors, and controllers. When the luggage machinery suddenly fails and does not work, or the working sequence is abnormal, fault diagnosis must be performed. Let us understand the method of diagnosing mechanical failure of luggage and bags from the three parts of the equipment.

1. Check all power, air, and hydraulic sources of automated luggage making machinery.

Problems with power supply, air supply and hydraulic supply will often cause mechanical failure of luggage. For example, power supply problems, including power supply failures in the entire workshop, such as low power supply, burned insurance, poor contact of power plugs, etc.; air pump or hydraulic pump is not turned on, pneumatic triple or double piece is not turned on, and the relief valve in the hydraulic system Or some pressure valves are not opened, etc. The following aspects should be included when inspecting luggage machinery:

Power supply, including the power supply of each equipment and the power supply of the workshop.

Air source, including air pressure source required by pneumatic device.

The hydraulic source, including the working condition of the hydraulic pump required by the mechanical hydraulic device of the luggage.

2. Check whether the sensor position of the luggage machinery is offset.

Due to the negligence of the equipment maintenance personnel, the position of some sensors may be wrong, such as not in place, sensor failure, sensitivity failure, etc. Always check the sensing position and sensitivity of the sensor, adjust in time if there is a deviation, and replace the sensor immediately if it is broken. In many cases, in addition, due to the vibration of the luggage machinery, most of the sensors will be loose after long-term use. Therefore, during routine maintenance, you should always check whether the sensor is in the correct position and whether it is firmly fixed.

3. Check the relay, flow control valve and pressure control valve of the luggage machinery

Relays are the same as magnetic induction sensors, they will also have ground adhesion after long-term use, so that the electrical circuit cannot be guaranteed and needs to be replaced. In a pneumatic or hydraulic system, the opening degree of the throttle valve and the pressure adjustment spring of the pressure valve will also loosen or slip with the vibration of the equipment. These devices, like sensors, are parts that require routine maintenance in luggage machinery.

4. Check electrical, pneumatic and hydraulic circuit connections

If no problems are found in the above three steps, then check all circuits. Check whether the wires in the circuit are disconnected, especially whether the wires in the wire groove are cut by the wire groove due to pulling. Check the trachea for damaged creases. Check if the hydraulic oil pipe is blocked. If the trachea has severe creases, replace it immediately. The hydraulic tubing should also be replaced.

5. After ensuring that the above steps are correct, the fault may appear in the controller of the luggage machinery, but it can never be a program problem. First of all, don't be sure that the controller is destroyed. As long as there has not been a serious short circuit, the controller has short circuit protection inside, and a general short circuit will not burn the controller.

Direction of development

Automated luggage making machinery is an organic combination of traditional manufacturing technology with modern information technology, management technology, automation technology, and system engineering technology. Through computer technology, it is the organization, operation, management and technology related to the entire life cycle of enterprise products. Integrate and optimize operation, realize informatization, intelligence, and integration optimization in the whole life cycle of enterprise products to achieve the goal of quick product launch, good service, high quality and low cost, thereby improving the flexibility, robustness and agility of the enterprise. Be invincible in the fierce market competition.

development trend

(1) Automation of luggage making machinery.

(2) Precision engineering testing.

(3) The improvement of traditional processing methods and the development of non-traditional processing methods.

(4) Intelligent manufacturing system.

(5) Computer-aided design and manufacturing integration.

Custom message