Ⅰ.Core Principles of Vacuum Forming

1. Thermoplastic deformation: Plastic sheet (0.3-3mm) is heated to glass transition temperature by infrared (such as ABS: 110-130℃)

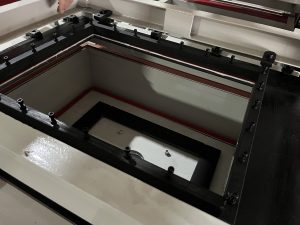

2. Vacuum adsorption forming: 0.08-0.1MPa negative pressure adsorption forming is formed through the vacuum hole of the mold (aperture 0.8-1.2mm)

3. Cooling and shaping: Water cooling system (5-15℃) or air cooling to achieve rapid shaping (cooling time accounts for 30-40% of the cycle)

II. Material engineering selection

1. Commonly used material comparison:

– ABS: tensile strength 40-50MPa, suitable for hard box

– PP: flexural modulus 1.5GPa, suitable for lightweight design

2. Thickness selection:

– Small box: 1.0-1.5mm

– 28-inch suitcase: 2.0-2.5mm

– Industrial protective box: 3.0mm+

III. Key points of process control

1. Temperature curve management:

– Preheating zone: 160-180℃ (sheet softening)

– Forming zone: 120-140℃ (maintain ductility)

– Cooling rate: ≥15℃/min (prevent crystallization defects)

2. Vacuum timing control:

– Pre-blowing delay: 0.5-1.5s

– Main vacuum duration: 3-8s

– Demolding backblowing pressure: 0.02-0.05MPa

3. Mold design criteria:

– Demolding slope ≥3°

– Fillet radius R≥2t (t is material thickness)

– Rib aspect ratio ≤5:1

IV. Innovative technology trends

1. Composite structure molding:

– EVA/plastic sandwich blister (shock absorption performance increased by 40%)

– Embedded hardware synchronous molding technology

2. Intelligent control:

– Infrared thermal imaging real-time monitoring of temperature field

– Adaptive vacuum system (PID dynamic adjustment)

3. Sustainable manufacturing:

– Bio-based PLA material application (carbon footprint reduced by 60%)

– Online waste recycling system (recycling rate > 85%)

V. Cost optimization strategy

1. Improved mold life: surface DLC coating (life extended by 3-5 times)

2. Energy consumption control: waste heat recovery system (energy saving 15-20%)

3. Material utilization: Nesting algorithm optimization layout (saving 8-12%)

The blister process is particularly suitable for boxes that require complex curved shapes (such as photographic equipment boxes and medical equipment boxes). Its unit cost is 30-50% lower than injection molding (in small batch production). It is recommended to combine FEA simulation to verify the stretch ratio and establish a DOE experiment to optimize the process window.