Contact Bonnie for quotation now:

Bonnie Zhang

Qingdao Suiteque Machinery co.,Ltd

Address:Tieshan Industrial Park,jiaonan District,Qingdao City,

Shandong Province,China

Postcode:266400

Website:www.qdxuqing.com

Alibaba Website:http://suiteque.en.alibaba.com/

Cell phone:+8615092093091

QQ:329201642

Our company

Specialized in making machines for more than 20 years in domestic and oversea market, its bran Multwin, he research and invent practical, high efficency compressed plastic bottle cap machine in technology field as his task, that's why he winning so much offer and will continue to provide best price for business partners.

Material of the Machine

1)Raw plastic mould steel and BeCu imported from Germany, quick heat conduction and dissipation to make rapid cooling of the caps therefore higher productivity.

2)High precision of mold accessories to make good coordination of each other.

3)Technology adopts nice heat treatment so as to achieve external wearproof and no deformation of internal structure.

4)Special coating process after heat treatment to avoid abrasion and increase the mold life.

Product Parameters

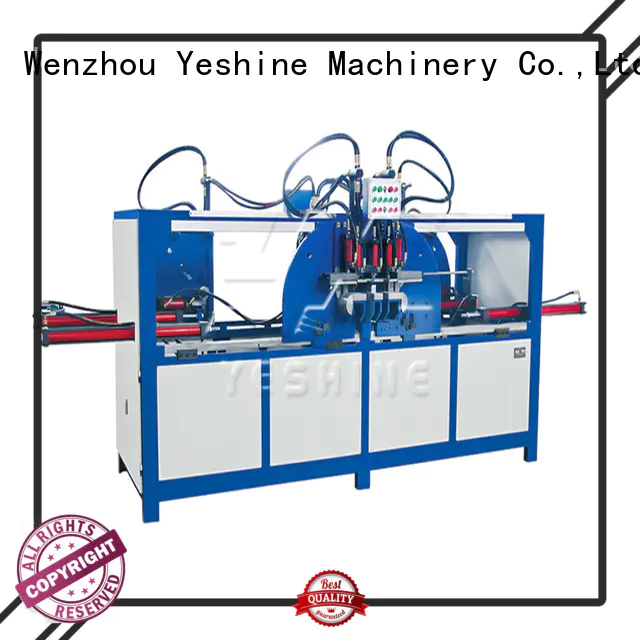

Picture of Our Machine

Mold Material

Die Steel S136 and BeCu imported from Sweden, anti-corrosion, good abrasion resistance and tenacity, good thermal fatigue resistance, uniform hardness, good polishing performance, high surface accuracy and easily heat conduction.

Advantages

1)Shorter cycle time, 14 circles/minute

2)Less energy consumption, lower production temperature

3)High productivity, triple productivities than injection machine

4)Eco-friendly, will not decompose

5)Low cost, each cavity is independent for maintenance

6)One can manage the machine instead of several workers

Our Service and our Team:

Perfect after sales to achieve win-win cooperation, we provide professional ways of using the machine and advise how to maintenace the machine, any technical problem will be solved in the end.

Manufacture Department

Achivements

1. Adopting integrated reversing valve

The selector valve inserted in the machine is our patent ,which, compared with plate-type reversing valve, is of advantages for lager flow,smaller volume,less internal leakage,lower differential pressure and longer lifetime.

2. Adopting built-in hydraulic flow channel

That means the feeding and returning of the hydraulic oil are totally formed in the flow channel punched by the inside components.The adoption of inner flow channel and integrated reversing valve make it unnecessary to use pipe to transfer the oil, which contribute to a cleaner inside for machine. Moreover, since our machine leaks less oil, it costs little to maintain; it adopts SMC connector for mold cooling water supplying.

3.Adopting reliable mold

Our supplier for mold is the manufacturer that also supplies machines to Sacmi. Materials of their molds are imported from Germany; molds will be treated with coating processing to ensure long operating life.

4. Adopting automatic rotary bearing

Slewing bearings are commonly used in cranes, excavators and other engineering machine. It can carry large axial, radial, and lateral force, which can normally service for more than 7-10 years.

Application

Contact Person: Demi Qin

Copyright © 2019 WENZHOU YESHINE MACHINERY CO.,LTD | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.