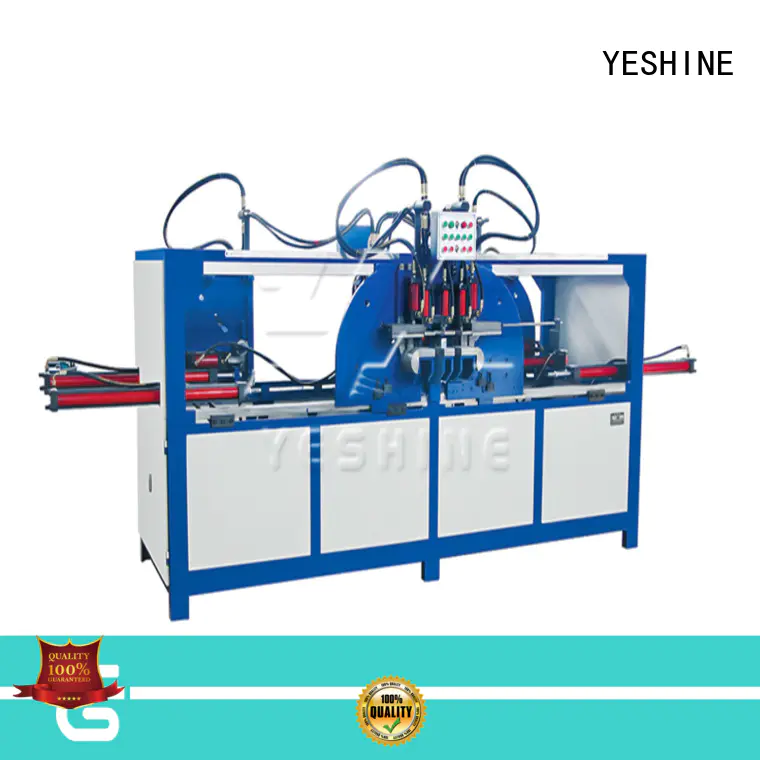

Vulcanizing Equipment advanced Rubber Compression Molding Machine, High Quality Rubber Vulcanizing Machine:

Details of rubber vulcanizing machine:

This series plate vulcanizing machine special-purpose takes shape the equipment for the rubber profession.Heats up the way to uses the electric heating(steam or oil heats up),the power uses the height combination to pump for the oil way, reduces the equipment the power loss.

The electrical control uses the advanced PLC control technology,may realize automati-cally controls when, automatically operates the mold,is automatic warm controls and so on the craft.And may realize automatically deflates. Thus guarantee product quality and high efficiency.

May have custom-made each kind of four columns,the frame type, the work table emigra-tion type,the work table emigration type in addition according to the customer product technological requirement and so on the many kinds of plates vulcanizing machine.

1.Main uses:

The Curing Press mainly works for the clampdown of rubber, which can be used as normal hydraulic machine.

We have both column and frame structure.

2.Advantages:

1. Simple and convenient structure, flexible operation,commodious space. The cylinder and plunger are made up of high–quality materials.

2. Hydraulic station and electric cabinet are Located in both sides of the main engine.

3. Conveniently operated.

4. Without oil spilling or off pressure.

5. Excellent reputation.

3. Technical Parameter as follows:

Type | XLB350*350*2 | XLB400*400*2 | XLB500*500*2 | XLB600*600*2/4 | XLB750*850*2 | XLB1000*1000*2 |

Total pressure(MN) | 0.25 | 0.5 | 0.8 | 1.0 | 1.6 | 2.5 |

Daylight(mm) | 125 | 125 | 125 | 125 | 125 | 200 |

Working layer number | 2 | 2 | 2 | 2/4 | 2 | 2 |

Plate size(mm) | 350*350 | 400*400 | 500*500 | 600*600 | 750*850 | 1000*1000 |

Plunger stroke | 250 | 250 | 250 | 250/500 | 250 | 400 |

Heating way | Electricity/steam | Electricity/steam | Electricity/steam | Electricity/steam | Electricity/steam | Electricity/steam |

Main motor power | 2.2 | 2.2 | 2.2 | 2.2 | 3 | 5.5 |

Stucture form | Strain rod | Strain rod | Strain rod | Strain rod | Strain rod/strain plate | Strain plate |

Model | 1200×1200 | 1500x1500 | 1800×1800 | 2000×2000 | 3000×3000 | 1300×6000 |

Nominal mould clamping force(MN) | 3.5/5.0 | 10 | 20 | 20 | 45 | 2.88 |

Plate size | 1200×1200 | 1500×1500 | 1800×1800 | 2000×2000 | 3000×3000 | 1300×6000 |

Number of working layer | 1 | 1 | 1 | 1 | 1 | 1 |

Cylinder number | 1 | 2 | 4 | 4 | 9 | 6 |

Piston diameter(mm) | Φ450/600 | Φ600 | Φ600 | Φ600 | Φ600 | Φ600 |

Stroke of piston(mm) | 200/500 | 700 | 800 | 700 | 800 | 250 |

Distance between hot plate(mm) | 200/500 | 700 | 800 | 700 | 1100 | 250 |

Unit area pressure of hot plate (Mpa) | S | 4.44 | 6.17 | 5.0 | 5.0 | 3.8 |

Main motor power(KW) | 5.5 | 13 | 20.5 | 20.5 | 61 | 23.5 |

Overall size (L×W×H)(mm) | 1920×1300×2160 | 4300×1600×4310 | 4400×1900×4965 | 4500×1900×4965 | 6500×5120×5500 | 6500×2200×3350 |

Weight(kg) | 8500/13000 | 32000 | 46000 | 50000 | 14000 | 8200 |

Close mould speed (mm/s) | ≥6 | ≥6 | ≥6 | ≥6 | ≥6 | ≥6 |

Open mould speed(mm/s) | ≥4 | ≥4 | ≥4 | ≥4 | ≥4 | ≥4 |

We can according to customers request design and produce all kinds of non-standard rubber vulcanizing machinery,

If you are interested in our products contact us freely,

our customers:

our workshop:

FAQ:

1.Q:Are you a factory or trading company?

A:We are factory.

2.Q:Where is your factory?How can i visit ?

A:Our factory located in qingdao city.You can fly to qingdao liuting airport,then we can pick you up to our facotry to visit.Warm welcome visit us.

3.Q:How does your factory control the quality of machines and after sales service?

A:Our machines passed CE,BV,ISO,SGS certification,pls confirm the quality.All our machines have 1 year guarantee, will provide lifetime maintenance.

Copyright © 2019 WENZHOU YESHINE MACHINERY CO.,LTD | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.